TF-75L

Low Level Feeder

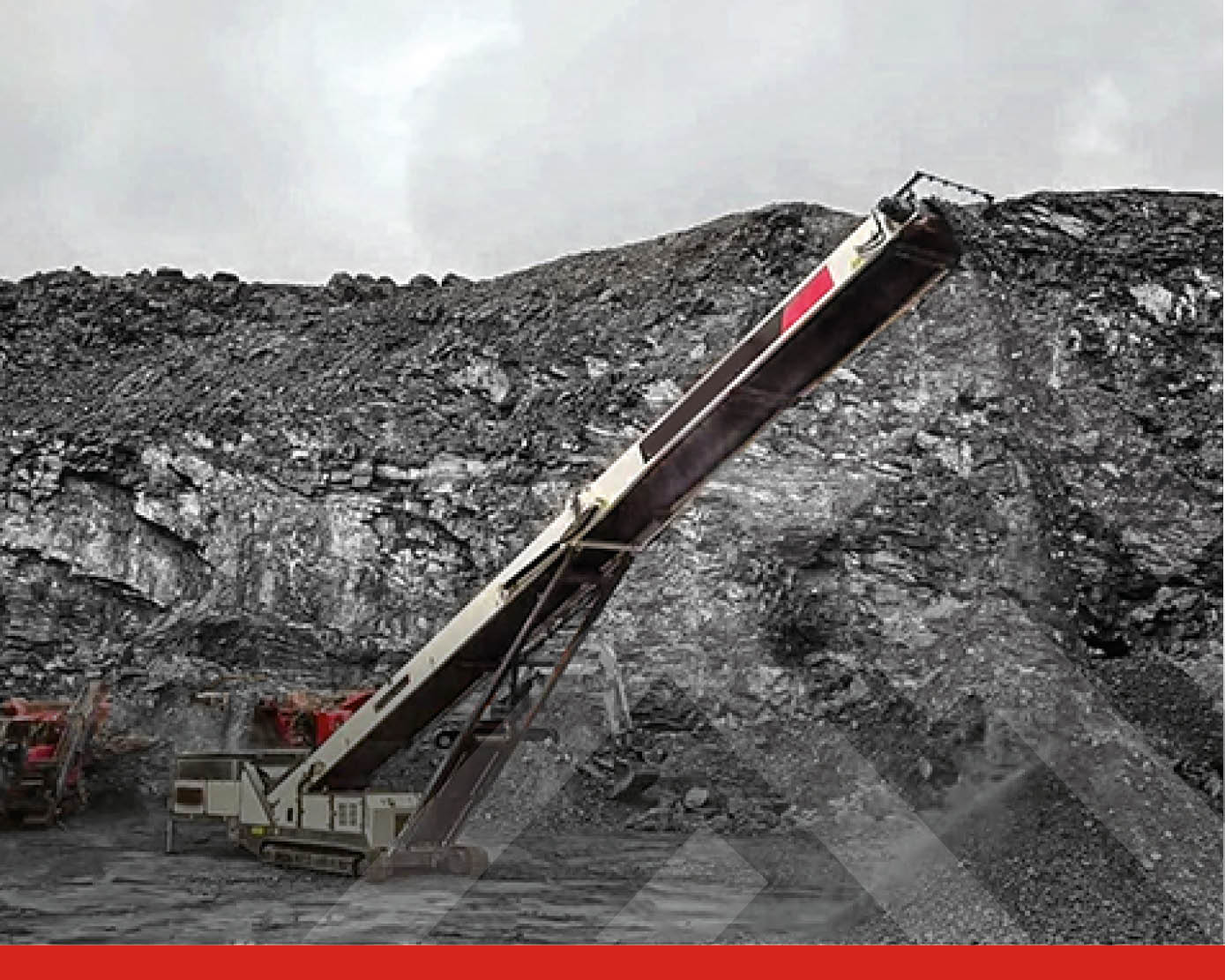

The Terex® Finlay TF-75L low level feeder has been designed to maximize productivity, enhance efficiency and reduce on site operational costs in a wide range of applications and feed material types.

The large 7m3 (9.2yds3) hopper with a feed in height of 1900mm (6’ 3”) and width of 3500mm (11’ 5”) enables low level feeding directly from excavators, grab cranes, and wheel loaders compared to standard high level feeders. For onsite safety and quick setup the hopper is fitted as standard with hydraulically folding sides.

Tracked mobility and the ability to feed material from all three sides enable the TF-75L to be easily incorporated into open and closed circuit static and mobile crushing and screening circuits.

For crushing and screening applications the machine can be used for a ‘metered or controlled’ feed of material. The machine can also be used to feed auxiliary equipment, connect to additional conveyors for transferring materials and to directly load / unload ships, trucks and rail wagons.

The machine is available with an orbital centre mounted slew bearing that enables 360° rotation and movement of the hopper/feeder to enhance on site mobility.

Key features:

- Inbuilt safety measures engineered into the machine include hydraulic feed height adjustment of the hopper and pinless deployment of the main conveyor.

- Hydraulic variable speed control of the feeder ensures efficient transfer from the hopper to the main discharge conveyor.

- The machine is available with hybrid technology consisting of on-board electrical motors permitting the flexibility to run the plant from an outside power supply or standard on-board engine.

- The machine features a 22.5m (73’ 10”) product conveyor that has the capacity to transfer up to 600tph (US 661tph) of material.

- Maximum stockpile capacity based on 37° angle of repose: 2776 tonnes (3060 US tonnes).

| Specification | Value |

|---|---|

| Conveyor Length | 75' / 22.6m |

| Belt Width | 48" / 1.2m |

| Max Discharge Height | 32’ 2” @ 24° / 9.8m @ 24° |

| Transport Dimensions | Width: 9' Length: 64' 9" Height: 11' / Width: 2.75m Length: 19.74m Height: 3.35m |

| Output Potential | 661 tph / 600 tph |

.png?sfvrsn=f0a0ba14_0)