Now, we see massive potential to bring that same value to global markets. A key focus of this work is educating international audiences on the unique safety, versatility, and operational efficiency that Franna cranes can offer. While the concept may be less familiar in global markets, the opportunity is clear and Franna is ready to redefine pick and carry crane solutions worldwide—just as we did in Australia."

“Franna pick and carry cranes are highly suitable for multiple industries across the UK due to their versatility, reliability, and superior capabilities,” said Pete Issitt, Managing Director, Crowland Cranes. “In fact, several Franna cranes are already in operation across the UK, and our team has been actively supporting them in the field. This hands-on experience has given us valuable insight, not only into the machines themselves but also into the technical and parts support provided by the team in Australia, which has consistently impressed us with their responsiveness, expertise, and reliability. We are therefore excited to showcase the Franna AT22-2 at Vertikal Days and demonstrate its potential to our wider customer base, the first new Franna crane to arrive in Europe for over 25 years.”

Another key region for Franna’s international growth strategy is the North American market. Danny explains more about the reception of articulated pick and carry cranes in the US.

One of the models being targeted for the US is the AT44 US, with lifting capacity of up to 44 US tons, a 3-axle design that eliminates the need for a removable counterweight. Additional features include a full width isolated cabin, articulating counterweight, and refined crane controls.

“There hasn’t been too many modifications required for the US model,” said Jaco Britz, Engineering Director at Franna. “Modifying to left hand drive and converting measurements, software, operator manuals and load charts, from metric to imperial were the obvious requirements. Franna is in the middle of an interesting project preparing the engine and hydraulics to operate in cold climate conditions, working with a Canadian company that is best-in-class at engineering these solutions.”

“We have been working hard to develop our international footprint and with that comes a significant amount of work relating to compliance and certifications,” said Jaco. “For example, in North America we are certifying the crane to ASME B30 and in Europe to EN 13000.”

“We’re also progressing road certification efforts in both regions,” added Danny. “Our recent work to meet Australian Design Rules (ADRs)—national standards for vehicle safety and emissions—aligns us with international benchmarks like Europe’s ECE regulations. For instance, the engineering work completed for ADR compliance has enabled us to use a dual-compliant engine that meets both European EU Stage V and USA EPA Tier 4f standards. This foundation will streamline the process of securing CE certification for the European market.”

The Franna models for international markets will also feature our patented Safety Radar, which has been very well received by crane operators. Danny explains more.

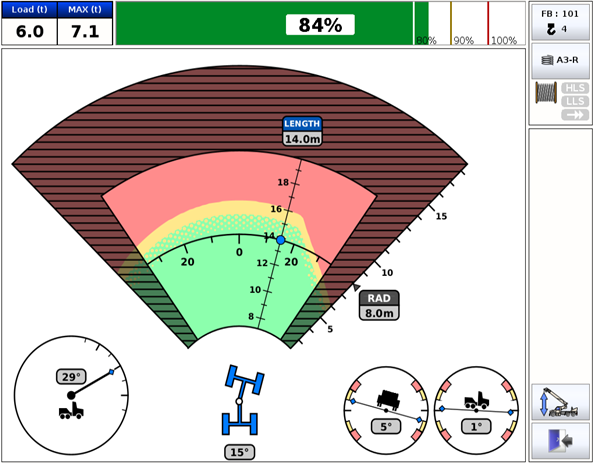

“Traditional Load Moment Indicators (LMIs) only give the operator the Rated Capacity for the current configuration the crane is operating in. But what happens to the Rated Capacity when the operator telescopes out, or articulates right? Most operators understand when they increase radius, the capacity of the crane reduces. But do they understand the difference between forward tipping and side tipping limiting Rated Capacities and how boom height and articulation effects this? Safety Radar takes it to the next level by providing the operator a clear visual representation of rated capacity changes in response to articulation and boom extension, for the entire working area, as can be seen in the diagram below. The blue dot at the crosshair of boom length and articulation angle shows where the crane is currently operating. The Safety Radar visual shows where the crane can operate and the colour contours reflect the Rated Capacity Percentage. The truncated line of red indicates a Rated Capacity limited by side tipping. This is invaluable information the operator has never previously had available and allows the operator to plan the next move. The Safety Radar visual also gives the operator an understanding of how the Rated Capacity drops off more quickly in a side tipping limitation as can be seen by the varying thickness of the yellow zone for forward versus side tipping conditions.

With one machine headed to the UK and others to the US, Franna is taking clear, tangible steps toward international growth. This progress is backed by decades of engineering expertise, patented technology, a strong track record in the Australian market, and a focused effort on taking the products through global compliance and certification standards. It's a significant step in demonstrating that a proven Australian solution is ready to exceed the needs of customers around the world.