AN ICON

REDEFINED

The latest innovation from Terex Washing Systems sees the launch of the M 1700X Mobile Washing Screener. The M 1700X - a redesign of the M 1700 - improves the M Range™ of mobile washing screens manufactured by Terex Washing Systems that can produce up to five products (three aggregates and two sands) in applications including; aggregates, recycling, industrial sands and mining.

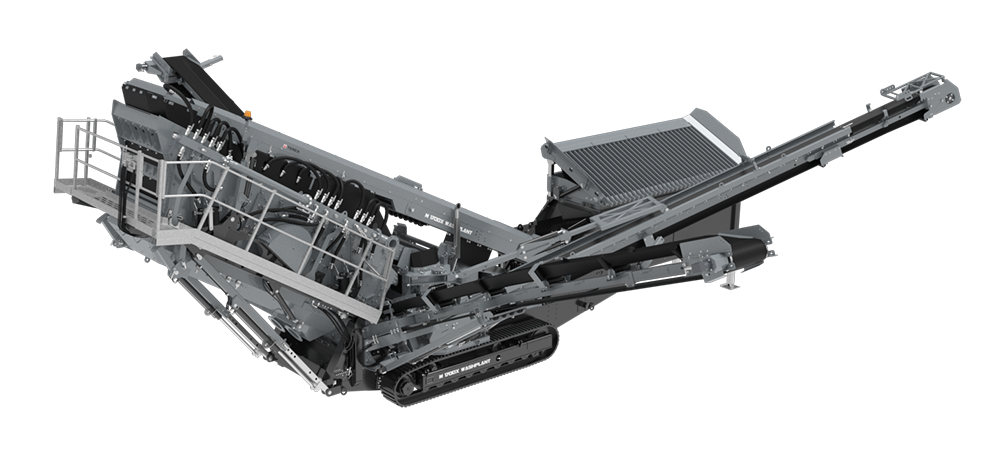

Track Mounted Washing Screener

The M 1700X allows users to wash and classify aggregates and sand on a mobile chassis. With heavy duty, low ground pressure tracks and hydraulically folding conveyors for transportation, this washing screener can be deployed in almost any environment. Perfect to small to medium sized operations the M-Range has already made a name for itself in the quarry, mining and construction and demolition industries.

Expert Engineering

Building on the success of the M 1700, Terex Washing Systems have redefined this tracked rinser using feedback gained directly from the end user. More features as standard, a one piece catchbox for easy machine reconfiguration and improved service access are just some of the improvements that have been made on this model. All of which result in less downtime and increased productivity.

Full Integration

The M 1700X, as with all Terex Washing Systems products, can be fully integrated with Terex crushing machinery. This unrivalled level of integration means the M 1700X can be part of a complete A to Z crushing, screening and washing system.

Power Unit

- Power unit featuring a transverse engine arrangement to aid access & serviceability

- Engine protection shutdown system

- High performance hydraulic system—cast iron pumps & motors complete with oil cooler

- Optional hybrid dual power and fuel save options available

Screening Technology

- Heavy duty fully riveted incline screen with adjustable stroke, angle & speed

- Screen mesh access system for quicker mesh changes

- Independently controlled spraybars for class leading rinsing

- All decks have brass nozzles and are designed to give full spray coverage

Highly Mobile

- Maximum mobility with heavy duty, low ground pressure tracks

- Removable heavy duty pendant remote control system

- Hydraulically folding conveyors for easy transportation

Heavy Duty Hopper

- High capacity belt feeder up to 600 tph / 661 US tph (depending on media sizes & material type)

- Hydraulic tipping reject grid (4”) as standard with radio remote control tipping grid

- Maximum feed size 150mm (6’’)