Ideal for customers seeking high productivity, low operating costs, and maximum versatility, the CRH5064 is an indispensable solution. Its advanced design reduces maintenance, improves safety, and delivers consistent performance across diverse applications.

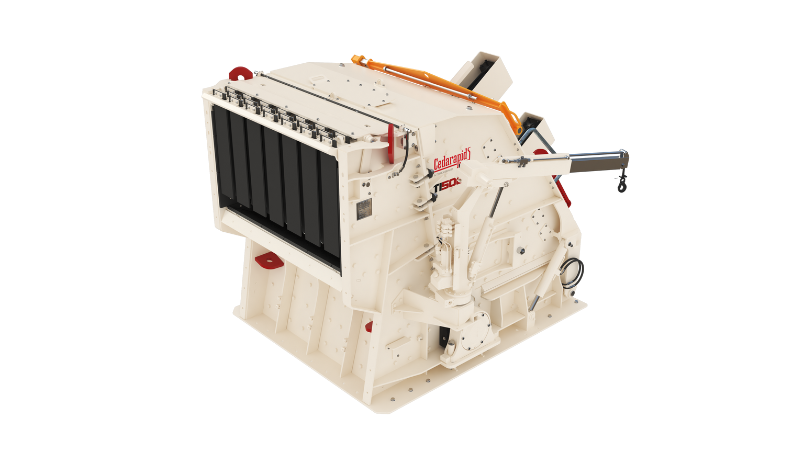

At the core of the CRH5064 is the powerful TI5064

Horizontal Shaft Impactor, delivering 400 hp of exceptional

performance. Engineered for today’s high-tonnage demands, this crusher combines

enhanced production with advanced safety features.

The TI5064 boasts a high-inertia 4-bar rotor, monoblock primary curtain with replaceable tips, hydraulic tramp iron relief, and hydraulic-assisted apron adjustments. These features maximize output while protecting the machine and operators. Prototype testing demonstrated impressive results, achieving 600–700 tons per hour through the plant when processing 30-inch minus shot rock limestone.

With a maximum feed size up to 30 inches, the TI5064 is the ideal solution for large-scale aggregate production, recycling, and demolition applications, delivering reliability and efficiency where it matters most.

Key enhancements incorporated into the TI5064 design are the patented hydraulic overload protection on both aprons, hydraulic assist apron adjustment, and a hydraulically opened hood for ease of inspection and maintenance. An optional jib crane and quick-release wedge lock system make changing blow bars easier. With proper site planning, no crane rental should be required for changing blow bars if equipped with the optional jib crane mounted to the structure of the crusher.

Another highlight to the CRH5064 plant is the new 60” x 20’ Cedarapids Advantage Series Feeder, which delivers exceptional production and long service life across the most rigorous applications. Its design is 8” wider than the largest previous model, maximizing crusher utilization and efficiency. Equipped with a large stroke, it achieves high throughput tonnage and superior material separation at the grizzly by removing fines early, feeding only what needs to be crushed to the crusher, ensuring optimal performance from the TI5064 HSI.

This combination ensures high production, low maintenance, and increased throughput, optimizing your operation and is ideal for a wide range of rigorous crushing applications; aggregate production as a primary crushing plant for quarry operations, or recycling & demolition, providing efficient handling of RAP and concrete recycling.

For added flexibility, a variety of options can be integrated, such as feed hopper extensions, hydraulic feeder lift option, blow bar jib crane, self-cleaning magnet, under-crusher pan feeder, electrical controls, and grizzly fines cross conveyors to suit your application. Designed with mobility in mind, the plant is configurable with various axle options, including standard quad, Washington spread quad, or 3+1.

A unique feature is the removable feed hopper module for increased transportability in challenging regions, offering a competitive edge in today’s demanding market. Future secondary crusher configurations are in process to feature a TSV Screen feed version or a belt feed version. Both secondary versions of the plant will replace the VGF section of the plant, typically of primary crushing operations.

Cedarapids is built with over 100 years of legacy expertise in portable crushing and screening plants in the aggregate and material processing industries. When it comes to investing in efficient and robust crushing equipment, experience matters!

Join Us at CONEXPO-CON/AGG 2026!

Mark your calendar for March 3–7, 2026, in Las Vegas and get an up-close look at the CRH5064 HSI portable plant, a powerhouse of productivity and innovation. Visit the Terex Booth SV2357 to see this robust crushing solution firsthand. Don’t miss the chance to experience why Cedarapids, a Terex Brand, continues to set the standard for efficiency and performance in large-scale operations.

.tmb-768x.jpg?sfvrsn=681540f_1)