Safety at Terex

At Terex, safety is an absolute way of life. We are committed to Zero Harm, and we expect all team members to be committed to this goal and to each other for continuous safety improvement. Safety culture is deeply ingrained in our business, empowering our teams to prioritize safe work practices. We provide our team members with the tools, training, and systems needed to plan and perform their work safely. All team members are expected to pause any job if they encounter or observe an unsafe condition, at-risk behavior, or any situation that poses a risk to the team. Our leaders are expected to foster a culture of safety, ensure that their teams are equipped for safe operations, and support pausing a job.

Life Saving Behaviors

Nine Life Saving Behaviors have been identified as crucial for preventing the most severe incidents. These non-negotiable rules are mandatory for all team members to follow and are supported by our Company's Safety Leadership Standard Work, which sets expectations for leaders throughout the organization.

I protect myself

against falls when working at heights.

I stand clear

of the danger zone from unstable/suspending tools.

I verify isolation

- lock tag and try - when work involves hazardous energy.

I follow

my lifting plan: No Plan. No Lift.

I obtain authorization

and validate air quality before entering a confined space.

I check

that my interlocks and guarding work correctly on my equipment and never bypass them.

I wear

my seat belt.

I position myself

in a safe zone in relation to moving equipment.

I pause

and ask for help from my supervisor if a condition is not safe or I cannot take these actions. If a near miss occurs, I report it immediately.

Total Recordable Incident Rate & Lost Time Injury Rate

We are seeking to achieve a Lost Time Incident Rate of 0.49 and a Total Recordable Incident Rate of 1.8 by year-end 2024. We encourage and empower team members to report Near Misses and have seen success with this metric, as evidenced by increasing numbers of these reports. This is a key indicator of increased awareness and engagement in safety initiatives. It is also a contributor to our overall decrease in recordable injuries.

Injury Prevention Behaviors

The Injury Prevention Behaviors (IPBs) at Terex are fundamental to keeping our team members safe. These behaviors have been carefully developed and are based on the most prevalent risks faced by our workforce, making them crucial in preventing injuries.

Seek Help for Discomfort

Don’t Use Excessive Force

Careful Material Handling

Firm Foundation

Keep Hands and Fingers Clear of Machines

Always Wear Gloves

Follow Standard Work

Know What Moves

Report Near Misses

Innovative Products That Promote Safe Working Practices

Product Quality & Compliance

Our goal is that every machine coming out of our plants is high in quality and free from defects. Zero-Defects is a key element of the Materials Processing Operating System. Zero-Defect KPIs are tracked, and countermeasures are implemented when required. Quality and safety go hand-in-hand.

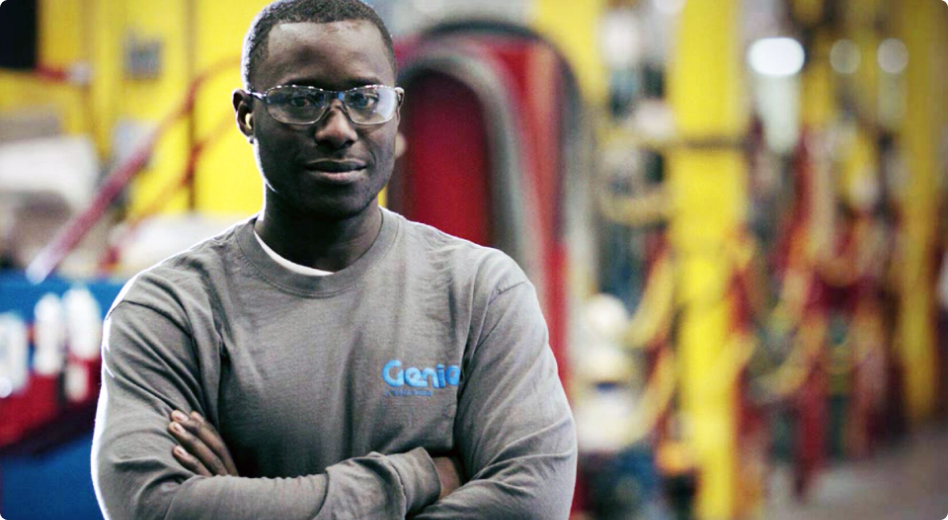

More than two years ago, Genie introduced its “Quality By Design” brand promise, which reinforces Genie’s commitment, dating back nearly 60 years ago, to deliver quality for customers and team members. Quality By Design encompasses all aspects of Genie’s operations and is integral to the manufacturing process — consistent with the Terex goal of manufacturing high- quality, zero-defect machines.

Terex remains committed to protecting our customers and product users by purchasing, designing, manufacturing, and selling safe products in compliance with standards and regulations for the markets in which we conduct business. This commitment necessitates our participation with industry organizations and standards development committees, as well as the continuous monitoring of regulations globally to ensure our products remain in compliance.

Key product quality and compliance legislation includes:

.png?sfvrsn=68cf48ce_10)

Committed to Culture and Inclusion

Helping Team Members Reach Their Full Potential

Engaged, capable, and highly skilled team members are key to successfully implementing our Execute, Innovate, Grow business strategy.

Engaged and Involved In Our Local Communities

As stated in our Purpose, our products help improve the lives of people around the world. We help build hospitals, schools, and critical infrastructure.

The Terex Services branch

in Watertown, South

Dakota, US helped sisters

at the Mother of God Monastery

with installing a rope on their

flagpole using a bucket truck.

The Terex Services branch

in Watertown, South

Dakota, US helped sisters

at the Mother of God Monastery

with installing a rope on their

flagpole using a bucket truck.

Terex Campsie,

Northern

Ireland,

sponsored a charity

event to support team

member Ciaran Conway

as he prepared for his

climb up Mount Everest

to raise money for

the Multiple Sclerosis

Society.

Terex Campsie,

Northern

Ireland,

sponsored a charity

event to support team

member Ciaran Conway

as he prepared for his

climb up Mount Everest

to raise money for

the Multiple Sclerosis

Society.

Team members from

our Terex Norwalk,

Connecticut, US

office packed food bags

to support Filling in the

Blanks, whose mission is to

fight childhood hunger by

providing children in need

with meals on the weekends.

Team members from

our Terex Norwalk,

Connecticut, US

office packed food bags

to support Filling in the

Blanks, whose mission is to

fight childhood hunger by

providing children in need

with meals on the weekends.

The Genie UK team continued

its annual tradition of donning

festive sweaters to raise

money for Save the Children. The team

also participated in a charity walk, which

raised funds for Mind, an organization

that provides support for individuals

experiencing mental health problems.

The Genie UK team continued

its annual tradition of donning

festive sweaters to raise

money for Save the Children. The team

also participated in a charity walk, which

raised funds for Mind, an organization

that provides support for individuals

experiencing mental health problems.

Terex Coalville,

England,

participated in a

CEO Sleepout, a

charitable event that

brings business leaders

together to make a

stand against

homelessness.

Terex Coalville,

England,

participated in a

CEO Sleepout, a

charitable event that

brings business leaders

together to make a

stand against

homelessness.

The Genie Netherlands team

participated in the largest Dutch

volunteering days, the NL Doet

initiative, and supported the foundation

Just Grow by helping to check and sort flag donations the organization had received.

The Genie Netherlands team

participated in the largest Dutch

volunteering days, the NL Doet

initiative, and supported the foundation

Just Grow by helping to check and sort flag donations the organization had received.

The Terex

Fontanafredda,

Italy team raised

funds for the Centro di

Riferimento Oncologico

(CRO), an Italian oncology

center of excellence located

in Aviano.

The Terex

Fontanafredda,

Italy team raised

funds for the Centro di

Riferimento Oncologico

(CRO), an Italian oncology

center of excellence located

in Aviano.

Members of

the Terex

Changzhou,

China team and their

families gathered to join

a community hike to

raise funds in support of

buying milk for children

in impoverished areas.

Members of

the Terex

Changzhou,

China team and their

families gathered to join

a community hike to

raise funds in support of

buying milk for children

in impoverished areas.

Genie Australia supported the

Trails for Change challenge, raising

donations and support to bring used and

excess medical equipment and supplies to

countries in dire need of them.

Genie Australia supported the

Trails for Change challenge, raising

donations and support to bring used and

excess medical equipment and supplies to

countries in dire need of them.

Charitable Contributions

One of our key values is Citizenship and we embody this value by encouraging our team members to get involved in their local communities. This could take many shapes and forms, but the one constant is that it happens. In 2023, Terex contributed to the non-profits below and others.

There is More

To learn more about our sustainability strategy, please read our 2023 sustainability report.

.png?sfvrsn=8e0c0ae4_12)

.png?sfvrsn=786480ca_12)

.png?sfvrsn=695d19b4_12)

.png?sfvrsn=fb093442_12)

.png?sfvrsn=68e37291_12)

.png?sfvrsn=4b917788_21)