Open Side Setting

Maximum distance between jaw die for a given setting (this is the distance when the jaw is at rest)

Close Side Setting

Minimum distance between jaw die derived from the OSS and the stroke.

Nip Angle

Inclusive angle between jaw die indicative of the crusher’s ability to crush and draw rock.

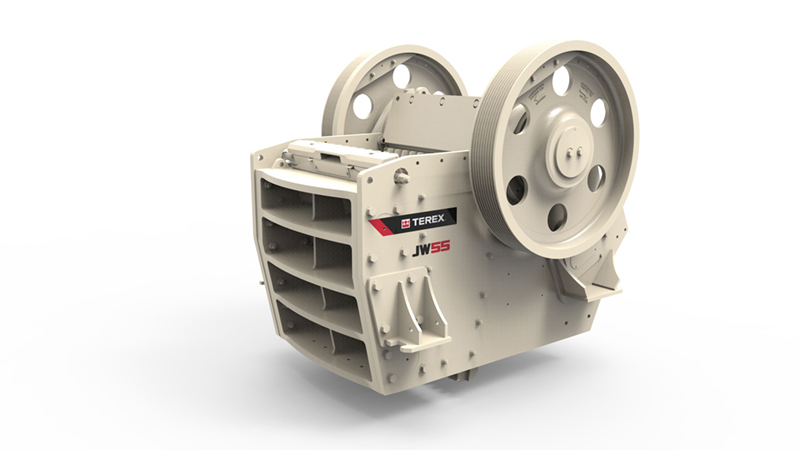

Fixed Jaw

Replaceable die attached to the fixed frame.

Swing Jaw

Replaceable die plate attached to the pitman.

Cheek Plates

Bolt on wear plates designed to protect crusher frame.

Wedges

Some designs of jaw crushers require wedges to ensure that the jaw plates are held firmly in position. These are also a wear part that can be replaced when worn down.

There are a few key points that you need to consider when selecting the correct liners for an application:

Jaw Die Profile |

Recycling | Soft-Medium Rock | Hard Rock | River Gravel | Asphalt |

|---|---|---|---|---|---|

Super Tooth |

X | X | X | X | |

| Quarry Tooth | X | X | X | X | X |

| Standard Tooth | X | X | X | X | |

| Multi Tooth | X | ||||

| Heavy Duty | X | X |