.jpg?sfvrsn=84ad5113_1)

Rotor

This is the main part of the HSI crusher. It holds the blow bars and rotates at a high speed, being driven by a pulley connected directly to the engine.

Blow bar / Hammers

Wear parts inserted into the rotor which impact the rock to cause breakage. These can be replaced when they are worn down. There are three different options:

Aprons

Primary and secondary aprons are used to reduce rock down to the required product size.

Apron Settings

This is the measurement the aprons are set at to achieve the product gradings. Always refer to machine specific operators manual for detail.

Apron Liners

Liners that are generally fitted to the end of aprons to ensure the apron settings can be maintained.

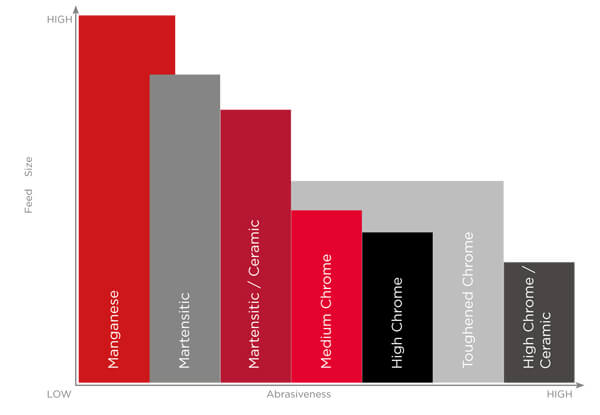

Manganese

Martensitic

Martensitic Ceramic

Chrome Iron

Chrome Ceramic

Toughened Chrome

Refer to the chart to help select the proper bar for feed size vs abrasiveness. If you have questions, please contact your dealer to discuss the specific details of your application.