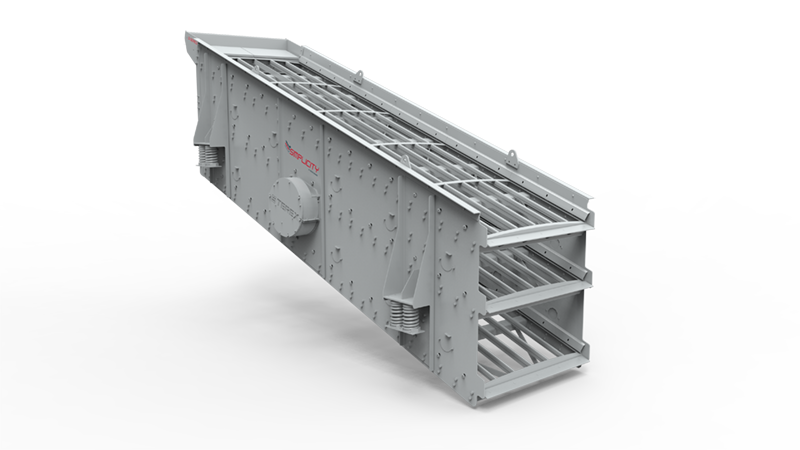

SI Series Screens from Simplicity - The Perfect Fit

Terex Minerals Processing Systems (MPS) have launched a new series of Simplicity range Standard Incline (SI) screens designed for heavy duty, medium and fine screening applications. “The SI screens are intelligently engineered to provide maximum value and long life. The screens are versatile and designed for easy maintenance. The large spacing between decks ease maintenance and quick media changes” said Edwin Sauser, MPS Product Manager.

The Si Screens are built with a robust drive mechanism and oversized bearings, these units can handle large tonnages and a wide variety of applications. Utilized as wet or dry screens, these units have adjustable stroke and speed combinations to fit your specific application and are available in 2 or 3 deck configurations.

They have many features which makes the screens more versatile and highly reliable in the market. They are fitted with woven wire media but can be converted into modular media with Polyurethane or Rubber media or steel plate without any cutting or welding.

The SI screens have the option of operating with grease or oil lubrication. An Auto-Lubrication system is available with grease lubrication. Side plates are made of hot rolled semi-killed/killed steel and the decks along with reinforcement plates are Huck bolted to the side plates. The robust tubular deck frames are made of hollow sections and fabricated structures.

Feed tray and discharge lips are provided with Abrasion Resistant liners. The screen box is made of weld-free construction to reduce stress concentration. The screen mechanism consists of steel eccentric shaft mounted in Vibration Screen Duty Self Aligning Spherical Roller Bearings designed for longer bearing life. The stroke can be adjusted as per requirement by changing the counterweights mounted on the flywheels.

The screens can also be converted into a rinsing screen by adding the rinser kit at site. Optionally, the screens are also available with dust encapsulation arrangement.

For further information please contact Michelle Murphy at +44 781 0441 386 or e mail michelle.murphy@terex.com