Terminology

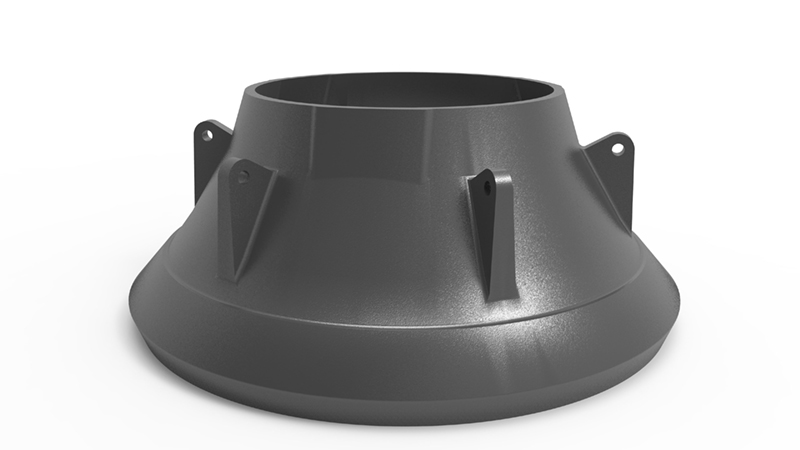

Mantle

Covers the cone head of the crusher to protect it from wear.

Concave (Bowl Liner)

Sits in the upper frame of the crusher to protect it from wear.

Backing Compound

A resin that is poured behind the manganese liners to fill the void and secure the manganese liners.

Open Side Setting (OSS)

The maximum distance between concave and mantle at a given close side setting.

Close Side Setting (CSS)

The minimum distance between concave and mantle to give the required output and grading for a machine.

Mantle Nut

Used on the top of the mantle to secure the mantle in place on the cone head.

Cone Liner Selection

There are a few key points that you need to consider when selecting the correct crushing chamber:

- Feed Size: Each chamber configuration has a maximum feed size that it can accept.

- Feed Grading: The maximum feed size is important; if there are a lot of fines in the feed or a lot of single size in the feed, it can cause issues with wear and output.

- Output required: This takes into account gradation required, which can affect which crushing chamber you should select.

Wear Performance

Machine factors that affect wear part performance:

- Speed

- Stroke

- Close side setting

- Feed arrangement (choke fed)

What is Choke Fed?

Choke Fed (Correct Method)

Result = Uniform Liner Wear

Trickle Fed (Incorrect Method)

Result = Irregular Liner Wear

- If there are a lot of fines in the feed or a lot of single size product in the feed, this can cause issues with wear and throughput.

- Can also cause “OUT OF ROUND” issues with liners