Terex MPS Plant Supplies Aggregates to Pan Borneo Highway Project, Malaysia

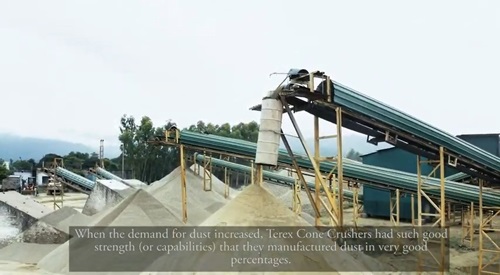

Malaysian-based quarrying and asphalt company (Asas Nikmat Sdn Bhd, ANSB) has selected a 350tph Terex MPS plant to supply steady, reliable aggregates for the Pan Borneo Highway Project, Malaysia.

The Pan Borneo Highway (PBHS) is Malaysia's biggest road project that spans over 2000km, connecting two East Malaysian states together, Sarawak and Sabah. Once complete, the PBHS will establish a transportation backbone and deliver significant economic benefits to the region.

Construction of such a major infrastructure project relies on securing a reliable supply of aggregates of suitable quality. ANSB, one of the local aggregate producers selected for the job, turned to Terex MPS for a solution that would meet their needs.

“Our previous dealings with Terex MPS gave us confidence that their equipment is reliable and well-engineered,” said Andrew Wah, Director, at Asas Nikmat Sdn Bhd. “We required a plant that could provide a large output capacity while having the flexibility in producing different types of aggregates, based on the project’s demand.”

The solution was a 350tph Terex MPS plant, consisting of a ST47 Single Toggle Jaw Crusher that features large gape feed openings, high production and low operating costs. These rugged machines are manufactured with heavy duty parts for constant operation and long life. As well as this, the plant features three cones, G30 Cone Crusher (which suited the project’s need to be able to take in large lump of 345mm from the 6 by 9-inch tunnel), J35 Cone, and TC1000 Cone. Together this equipment provides a robust, reliable solution for feeding 700mm sandstone at approximately 350tph to produce -50 + 0 aggregates, to be used for road base throughout the highway project. It has been operating onsite for two years and will continue to perform for many years until the project has been completed.

“The equipment is performing above our expectations, delivering more capacity, better shaped product and requiring less maintenance,” continued Andrew. “What we have also appreciated is the support provided by Terex MPS—the team were a great help and resource during the planning and commissioning of the plant. They were able to communicate effectively with our team to ensure that it was optimised to meet our specifications while also achieving the robust safety, functionality and performance standards needed for our jobsite. The result is a plant that is operating effectively, with minimal downtime.”

Benjamin Tong, Sales Manager with Terex MPS said, “ANSB has an excellent reputation for providing their customers with the highest quality service and products that performs for their requirements. Having them choose Terex MPS for this large-scale construction project is a terrific testament to the safety and high performance of our equipment, coupled by the close aftermarket support we provide to our customers to make sure our equipment is operating as required.”