Tank Height

345 Inches - 511 Inches

8778mm - 13000mm

Tank Diameter

165 Inches - 315 Inches

4200mm - 8000mm

Capacity

13208 US Gal - 68684 US Gal

50000 Litres - 260000 Litres

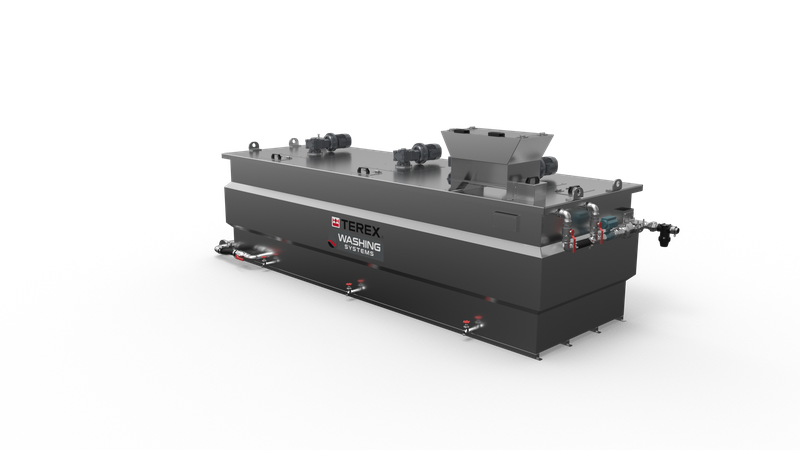

Overview

Save space and simplify maintenance with our Aqua Cone Thickeners, offering a compact, low-cost solution for high-efficiency sludge thickening, even in the toughest applications.

Save space and simplify maintenance with our Aqua Cone Thickeners, offering a compact, low-cost solution for high-efficiency sludge thickening, even in the toughest applications.

English

English