English

English

J. Mould Ltd, a family-run demolition and recycling business with over 45 years of experience, set out to turn its new Berry’s Lane headquarters near Heathrow into a high-performance hub for sustainable materials recovery.

The team set clear priorities:

Integrate water treatment to improve sustainability and reduce environmental impact

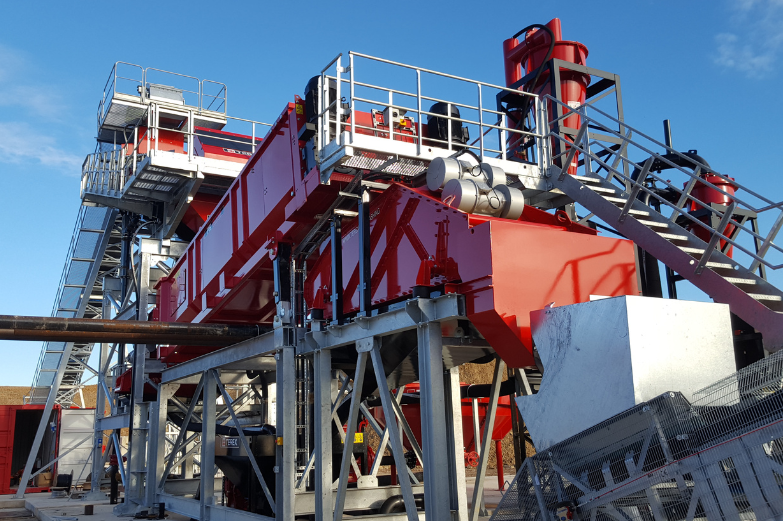

J. Mould Ltd partnered with Terex Washing Systems to install a 120tph custom wash and water treatment plant at their Berry’s Lane site. The compact setup is designed for efficient recovery, minimal handling, and long-term sustainability.

Key components include:

Central touchscreen control room for easy plant operation

Located near Heathrow and central London for easy access to key construction markets

-min.png?sfvrsn=544a497d_1)

Circa 200tph processing