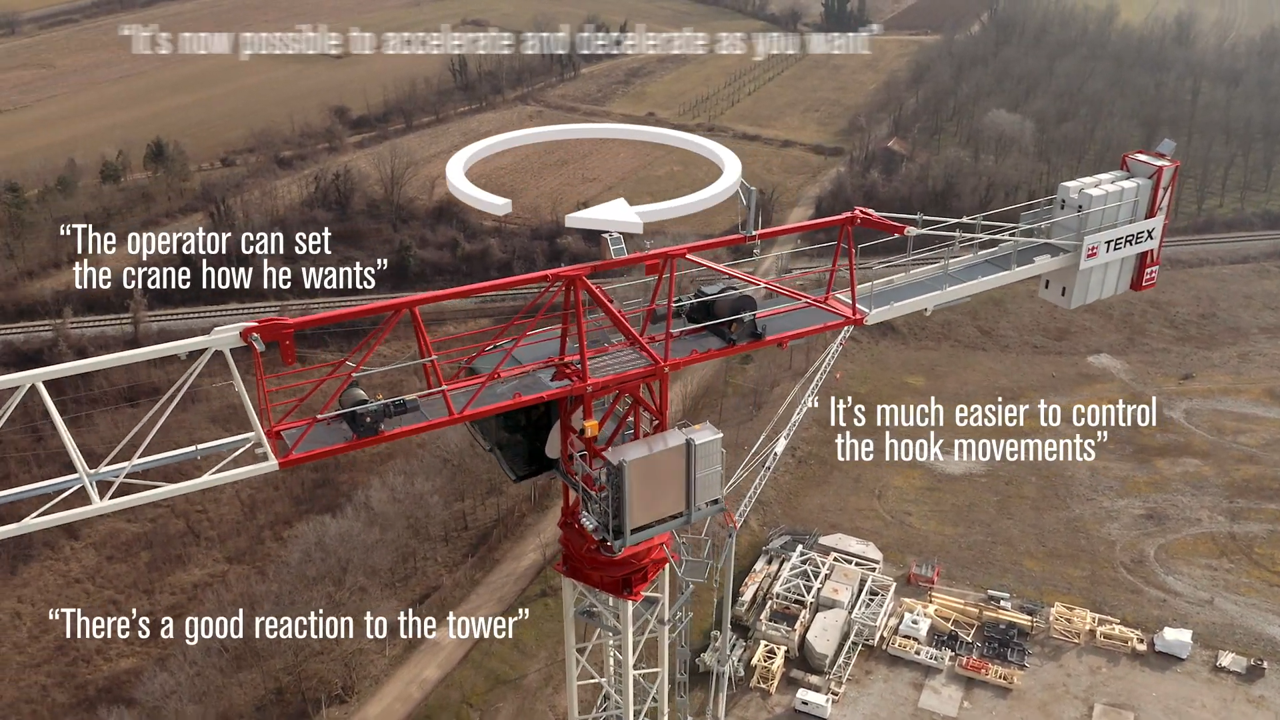

Ultimate Control Over Crane Slewing with T-Torque Technology

Terex Cranes has recently introduced its latest T-Torque technology across a selection of tower crane models to enable precise control and quick, flawless responses to operator commands.

T-Torque is based on inverter technology with torque control applied directly to the slewing motors. From the intuitive touch screen control panel in the cabin, T-Torque allows operators to accurately define and customize settings—including, start-up boost, acceleration, deceleration, counter-manoeuvres and speeds—based on their preferences or on specific operating conditions, such as crane configuration, load type or wind speed.

The crane immediately responds to the operator’s command, and jib slewing can be adjusted to be smoother or more powerful, giving the operator accurate control of load handling and positioning, which is critical on congested jobsites. Additionally, operators can save their customized settings for a quick crane setup.

T-Torque is the result of a long design process that has been driven by a study of operator behavior and from feedback on their needs and problems. It has been well-received by experienced crane operators who have rigorously tested the new technology, with initial feedback including; “It is great that the operator can set the crane how he wants!” and “It is now possible to accelerate and decelerate as you need to”.

Currently T-Torque technology is available on models CTT 132-6, CTT 172-8, CTT 202-8, CTT 202-10, CTT 472-20, CTT 332-16, CTLH 192-12 and CTL 282-18, but given the positive market response, the range will be expanded in the future!

View T-Torque technology in action here!