English

English

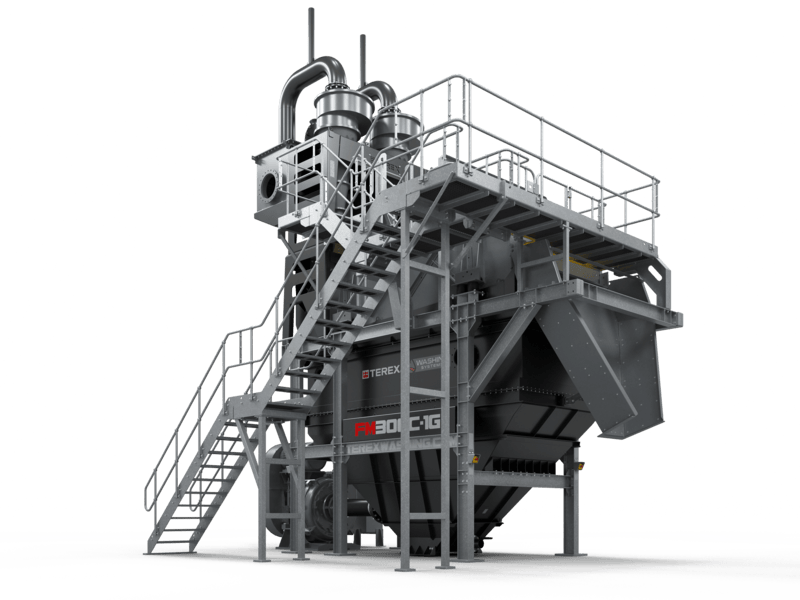

The FM 300 Compact™ is the largest sand washing unit in the FM Compact™ range, offering up to 300 tons per hour (tph) of dewatered sand on a single compact modular chassis, engineered for cost and energy savings.

This makes it the ideal solution for quarries and operators seeking clean, spec-compliant sand with a minimal footprint.

Using centrifugal force within high-efficiency hydrocyclones, the FM300C effectively removes clay, silt, and slime from feed material, producing up to two grades of clean sand. With robust wear protection, smart water management, and easy maintenance access, this plant is built for performance and longevity.

.png?sfvrsn=d5eeda0f_1)

Key Benefits of the FM300C Sand Washing Plant