New 'HOTSPOT' Website Feature

Terex® Finlay are pleased to present our new website HOTSPOT feature.

The HOTSPOT feature has been designed to provide a simple and intuitive tool to help customers find detailed information about each Terex® Finlay machine.

Scroll down and check out the HOTSPOT feature now available for each of our mobile impact crushers.

Additional HOTSPOTS will be added to our website for each Terex® Finlay machine in the near future.

Terex® Finlay I-140 Impact Crusher

Main Conveyor

Impact Chamber

Hopper / Feeder

By-pass Conveyor

T-Link Telematics

The Terex® Finlay I-140 tracked impact crusher has an advanced technological design that gives improved material flow through the machine to produce precisely shaped cubical end products in quarrying, mining, demolition and recycling applications.

The high productivity, ease of maintenance and operation makes the machine an ideal solution for large scale producers and contact crushing operators.

The machine is built around a robust direct drive Terex® CR032 Ø1270mm x 1220mm (Ø50” x 48”) impact chamber crusher.

Terex Finlay I-140 Impact Crusher (Quarry)

Terex Finlay I-140 Impact Crusher (Quarry)

.tmb-768v.jpg?Culture=en&sfvrsn=eb496cb0_1)

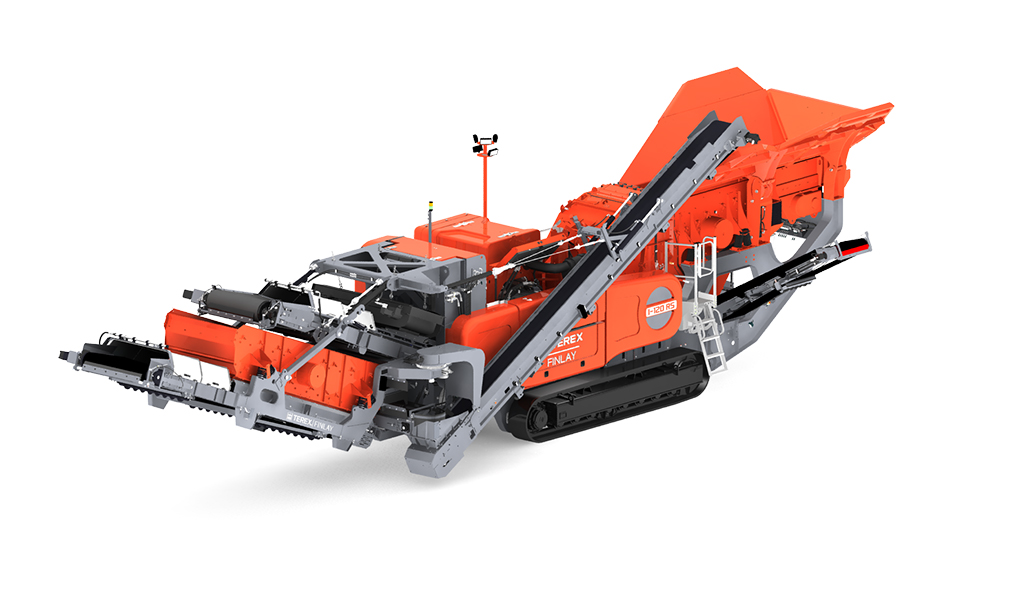

Terex® Finlay I-140RS Impact Crusher

Hopper / Feeder

Detachable screenbox

Fines conveyor

Main conveyor

Impact chamber

BYPASS CONVEYOR

Re-circulating conveyor

T-Link Telematics

The Terex® Finlay I-140RS mobile impactor provides the flexibility of a tracked impact crushing and screening plant on one machine. The key component is the on-board detachable 4.8m x 1.5m (16’ x 5’) single deck screen. For applications not requiring recirculation of materials for further processing or stockpiling the complete screening and recirculating system can be quickly detached from the machine.

The recirculating conveyor can be rotated from closed loop configuration or utilized for stockpiling making an additional oversized product. The machine is built around a robust direct drive Terex® CR032 Ø1270mm x 1220mm (Ø50” x 48” impact crusher.

Terex Finlay I-140RS Impact Crusher (Quarry application stockpile mode)

Terex® Finlay I-120 Impact Crusher

Main Conveyor

Impact Chamber

VGF Hopper / Feeder

By-pass Conveyor

Undercarriage

Magnet Separator (Optional)

T-Link Telematics

The Terex® Finlay I-120 is a mid-sized track-mounted mobile impact crusher, commonly used for processing medium to hard natural aggregates and recycling materials such as asphalt, concrete and bricks.

For operators in recycling and demolition applications the options of an underpan feeder and auto adjust on the chamber secondary apron are also available for the machine.

The machine is built around a robust direct drive Terex® CR038 Ø1033mm x 1100mm (Ø41” x 44”) impact crusher.

Terex Finlay I-120 impact crusher & 684 inclined screen

.tmb-768v.jpg?Culture=en&sfvrsn=abf76a73_1)

Terex® Finlay I-120RS Impact Crusher

Main Conveyor

Impact Chamber

Hopper / Feeder

Bypass Conveyor

Re-circulating conveyor

Fines Conveyor

Screenbox

T-Link Telematics

The Terex® Finlay I-120RS provides the flexibility of a portable impact crushing and screening plant on one platform. The on-board innovative quick detach 3.66m x 1.53m (12’ x 5’) two deck screen ensures a quality cubical product.

For applications not requiring re-circulation of materials for further processing or stockpiling the complete screening and recirculating system can be quickly detached from the plant.

The machine is built around a robust direct drive Terex® CR038 Ø1033mm x 1100mm (Ø41” x 44”) impact crusher.

Terex Finlay I-120RS Impact Crusher (Concrete Recycling)

.tmb-768v.jpg?Culture=en&sfvrsn=1d9a4ebb_1)

Terex® Finlay IC-110 Impact Crusher

The Terex® Finlay IC-110 tracked compact impact crusher has been designed to provide high productivity in quarrying, construction and demolition debris, reinforced concrete and asphalt recycling applications.

The impact chamber features variable rotor speed and hydraulic apron setting assist to provide convenient and efficient adjustment of the chamber aprons. It is also fitted with hydraulic overload protection system as standard.

The machine is built around a robust direct drive Terex® Ø1034mm x 1000mm (Ø41.5” x 40”) impact crusher.

Terex Finlay IC-110 compact impact crusher

Terex® Finlay IC-110RS Impact Crusher

The Terex® Finlay IC-110RS mobile impactor provides the versatility of a compact crushing and screening plant on one mobile platform for quarrying, construction and demolition debris, reinforced concrete and asphalt recycling applications. A key feature of the machine is the onboard 2.74m x 1.5m (9’ x 5’) single deck screen.

For applications not requiring recirculation of oversize material back to the crushing chamber or stockpiling an oversize product the complete screening and recirculating system can be quickly detached from the machine.

The machine is built around a robust direct drive Terex® Ø1034mm x 1000mm (Ø41.5” x 40”) impact crusher.

Terex Finlay IC-110RS compact impact crusher

Terex® Finlay IC-100 Impact Crusher

The Terex® Finlay IC-100 compact impactor has been specifically designed for quarrying, construction and demolition debris, reinforced concrete and asphalt recycling applications. The IC-100 provides operators with a compact and versatile machine that gives high material reduction ratios and produces a consistent product grading.

The compact size, ease of transport, quick set up times and intuitive operation make this machine ideal for contract crushers, independent rental houses and small scale operators.

The machine is built around a robust direct drive Terex® Ø860mm x 860mm (Ø34" x 34") impact crusher.

Terex Finlay IC-100 Compact Impact Crusher

Terex® Finlay IC-100RS Impact Crusher

The Terex® Finlay IC-100RS tracked impact crusher provides the versatility of a compact crushing and screening plant on one mobile platform for quarrying, construction and demolition debris, reinforced concrete and asphalt recycling applications.

The onboard recirculating and 2.44m x 1.2m (8’ x 4’) single deck screen can be be quickly detached from the machine for applications not requiring recirculation of oversize material back to the crushing chamber. The recirculating conveyor can be rotated from closed loop configuration and utilized for stockpiling making an additional oversized product.

The machine is built around a robust direct drive Terex Ø860mm x 860mm (Ø34" x 34") impact crusher.

Terex Finlay IC-100RS Impact Crusher (Concrete Recycling Application)

.tmb-768v.jpg?Culture=en&sfvrsn=226c769b_2)

Applications

![]()

Quarry & Mining

![]()

Sand & Gravel

![]()

Construction & Demolition

![]()

Recycling

.png?sfvrsn=f0a0ba14_0)