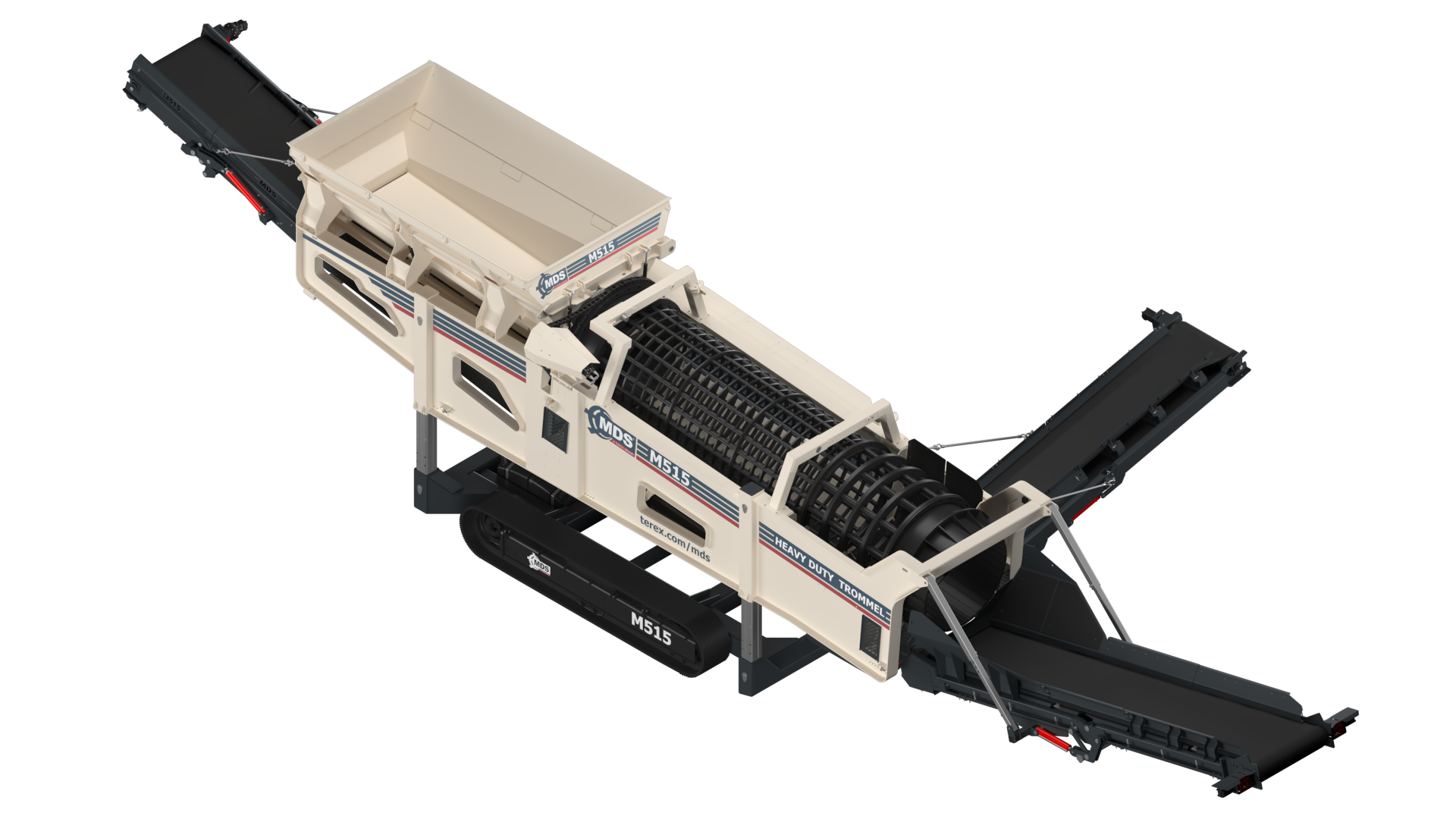

M515 Processing Coal

A Coal Mine in Pennsylvania faced challenges in efficiently feeding its coal plant with 0-3" (0−76mm) material. The customer aimed to minimize wear and reduce the number of machines required in the coal production process.

The Challenge:

The customers primary goal was to decrease wear on equipment and streamline the coal production process. Prior to implementing the MDS M515 Heavy Duty Trommel, the customer had been using a crusher to break up the coal, leading to increased wear and a higher number of processing machines.

The M515 Heavy Duty Trommel Solution:

The MDS M515 Trommel was identified as the optimal solution for the customer's challenges. The trommel was equipped

with lifters specifically designed for processing coal. This configuration allowed the separation of most rocks from the coal

without the need for a separate crushing stage.

Location: USA

Application: Processing coal

Machine: M515 Trommel

Machine Specifications:

3" (76mm) Heavy Duty Screens

6" (152mm) Heavy Duty Screens

10" (254mm) Tipping Grid

Lifters in the drum