Superior design and development capabilities equal high-end products

We transform businesses across a wide range of industries by designing and developing products with innovation and quality precision. Our unique expert capabilities to deliver cutting-edge products and meet exacting international standards are built on strong technical knowledge.

Product Testing and Validation

At Terex India Research Center, we have extensive experience in building prototypes and performing tests for meeting test objectives and assessing product performance. Our engineers conduct advanced component and product-level testing for heavy engineering and aerial work platforms.

We perform meticulous planning and execution of various static and dynamic tests at subsystem, sub-assembly, and integrated assembly levels. Our test-analysis correlation activities help us to deliver superior performance and precision quality.

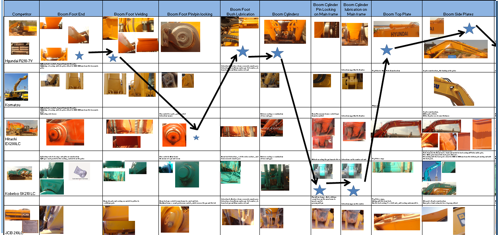

Product Benchmarking

We have adopted a systematic, well-defined approach for benchmarking that enables us to improve our product positioning in the market. Our team prepares a detailed report that includes insights regarding specifications and features of competitor products, both at machine and component levels. The report also categorizes and highlights the best specifications for component designs.

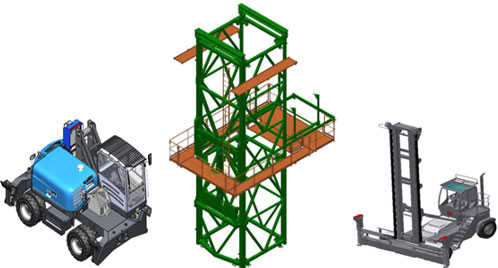

Legacy Data Conversions: 2D & 3D

At Terex India Research Center, we create 2D data in AutoCAD or tiff images for converting into 3D models and drawings as per the international standards. Our team uses advanced design software such as Pro-e, UG-NX, Solidworks, and Autodesk Inventor for this purpose. We also create standard parts libraries where we store our data in PDM software, including TCE, EPDM, or Windchill.

Engineering Change Management

We use a wide range of tools such as deviation descriptions, mark-up drawings, PPTs, and ECO/ECR forms to update the models, drawings, and PDM/ERP system. Our process includes the following steps:

Conducting an extensive problem study and impact analysis to understand the products or groups affected by the changes

Reviewing observations on site to modify 3D models as well as update and create new drawing revisions

Complete ECO form and submit/notify downstream functions such as purchasing, planning, and quality

Developing an ERP system entry for BOM creation and updates

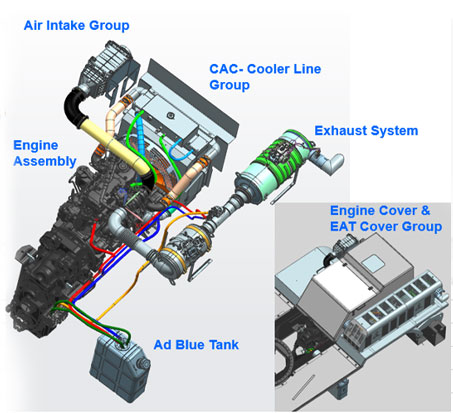

Engine Emission Management

We are an expert in implementing Tier-4F, EM4, and EM5 in Cummins, Volvo, Scania, Deutz, and MTU engines with upgraded versions. Our organization has earned a reputation for designing varied products as per engine manufacturer installation guidelines, such as:

- Fuel tank group

- Ad blue tank group

- Engine and transmission mounts

- New air intake system

- CAC group

- Engine coolant group

- Exhaust system

We perform structural modification on chassis and decking to accommodate new engine changes. Our other expert capabilities include electrical schematics and harness design, hydraulics hoses and tubes routing, vibration analysis on engine mounts, as well as testing and prototype build support.

.png?sfvrsn=3f403bf2_0)