5TPH Residual Municipal Solid Waste (MSW)

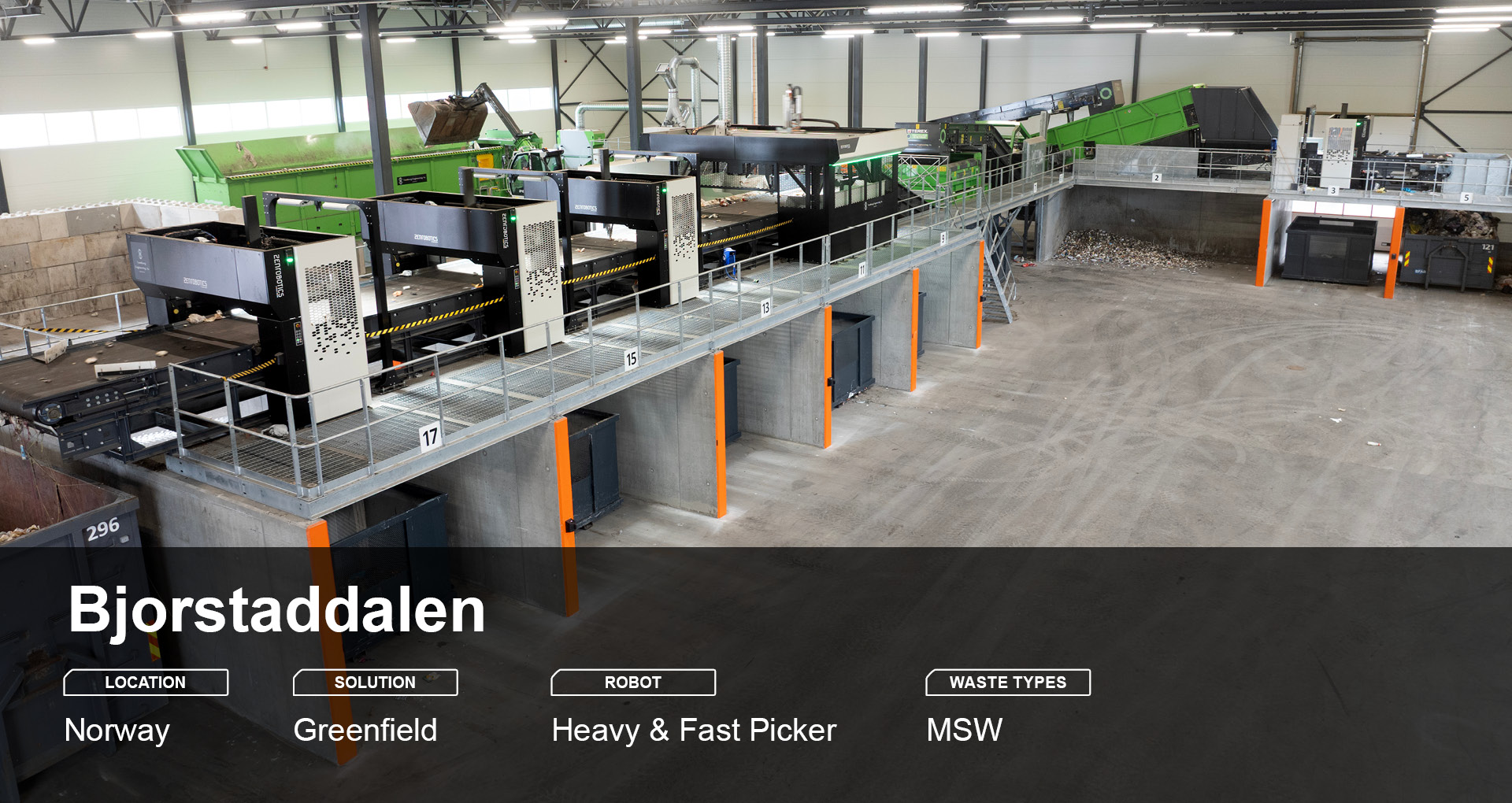

Bjorstaddalen, a prominent Norwegian waste management company, has commissioned a new Material Recovery Facility (MRF) to provide decentralised, cost-effective household waste recycling using equipment from ZenRobotics® and Terex® Recycling Systems.

Located to the south of Oslo in the municipality of Skien, the MRF is now fully operational and has demonstrated exceptional throughput and precision, processing 5 tonnes per hour of residual Municipal Solid Waste (MSW) without the need for any manual labour. This touch-free operation not only boosts efficiency but also enhances worker safety by eliminating exposure to hazardous materials and repetitive strain tasks.

Operations Manager of Bjorstaddalen.

Dual-Action Robotic Arms

.png?sfvrsn=48509761_0)