_oct.png?sfvrsn=d47276dd_1)

Inside Remeo's next generation recycling facility

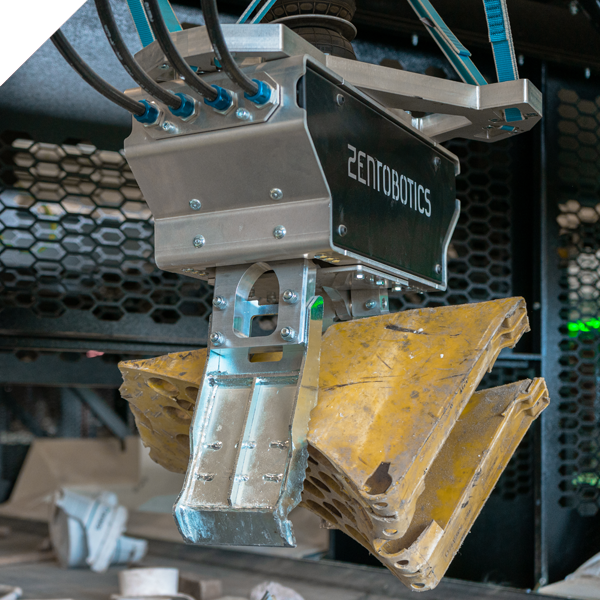

We collaborated with Remeo and STADLER to create the largest material recovery facility (MRF) in the world that uses robots in C&D and C&I waste recycling. STADLER designed the Materials Recovery Facility (MRF) in collaboration with Remeo and built it, while ZenRobotics supplied AI-based robotics waste sorting technologies. This state of the art facility has the annual processing capacity of an 120,000 tonnes of construction waste and 60,000 tonnes of energy waste produced in commerce and industry.

Together with Remeo, we’re giving vast amounts of C&D and C&I waste a new life by recycling it into high-quality alternatives to virgin materials. The Remeo facility, located in the capital region of Finland, hosts twelve robot arms in total and is among the first in the world to combine C&I and C&D processing lines.

The next generation facility hosts twelve robot arms in total and is among the first in the world to combine C&I and C&D processing lines.

The facility covers more than 30 percent of all waste recycling needs in the Helsinki region in Finland.

The world’s strongest sorting robots pick objects that weigh up to 30 kilograms and together perform up to 24,000 picks per hour.

Efficient recycling ensures exceeding the minimum 70% recycling rate

The facility will cover more than 30 percent of all waste recycling needs in the Helsinki region in Finland. As an added bonus, this mega facility also removes the need to export the waste from Finland. Previously, much of the waste was shipped abroad as there isn’t enough capacity to recycle it nationally. Remeo’s facility stops this with effective recycling close to the place of origin of the waste, cutting transport emissions while at it thanks to short distances. Due to efficient recycling capabilities, Remeo is also helping its customers to meet the minimum 70 % recycling rate required by the law - going at 71.8% after first months of operation.

The key part of achieving these numbers are the twelve ZenRobotics Heavy Pickers – the world’s strongest sorting robots that can pick objects that weigh up to 30 kilograms and together perform up to 24,000 picks per hour. Meaning, the robots do all the heavy lifting that’s neither safe nor feasible for humans. These smart robots at the Remeo facility are currently sorting fractions from four different types of waste: wood, metals, stone and plastics – and they’re trainable to recognise an unlimited amount of new fractions, too.

.png?sfvrsn=48509761_0)

_oct.png?sfvrsn=d53a6e42_1)