Quest to circulate and retain the complete value of C&D waste

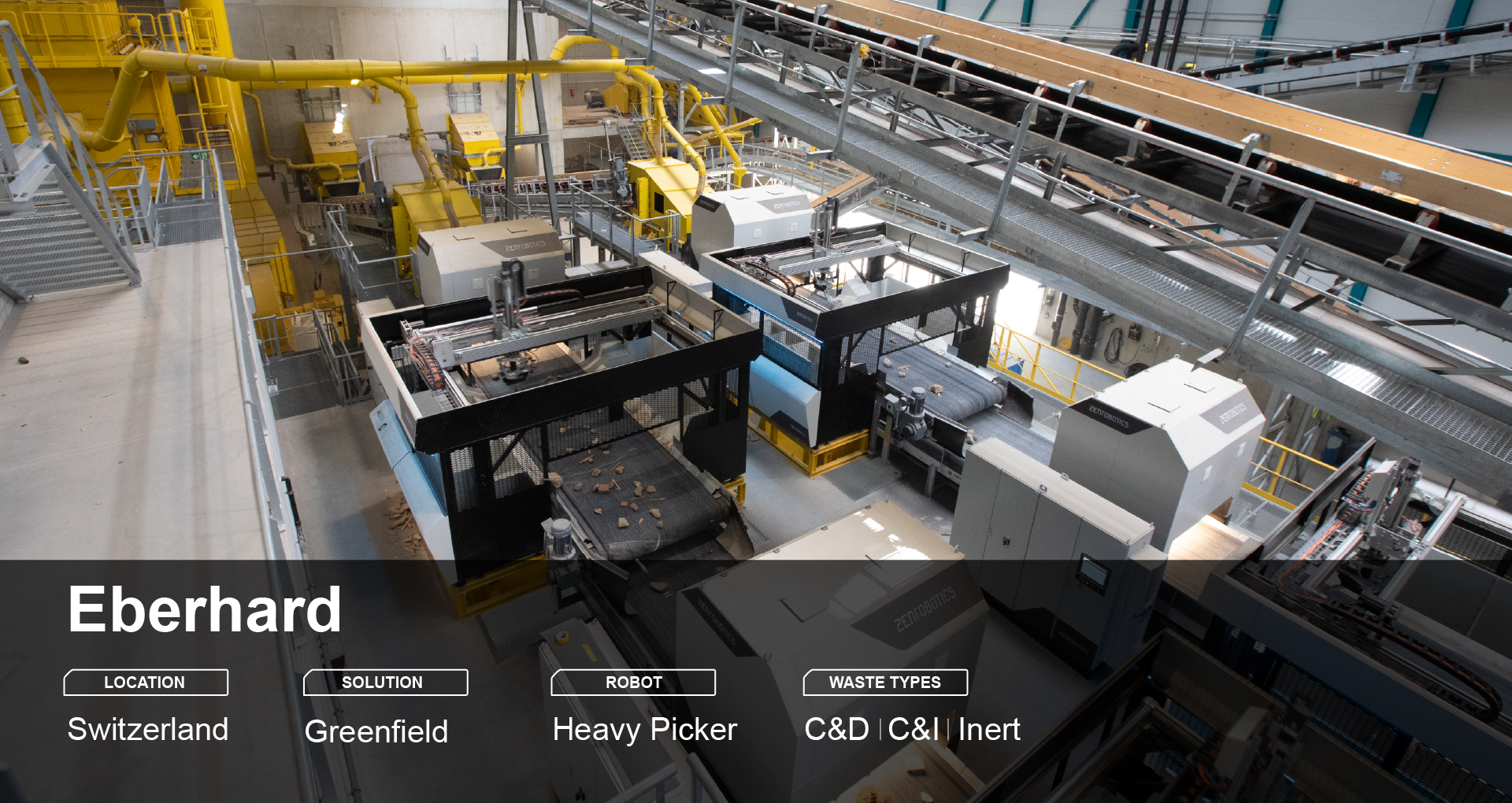

Did you know that after water, concrete is the most used resource of the world? Did you also know that mixed demolition waste is mostly used as a low-grade material, or even landfilled? The Eberhard Group, adamant to turn this grim take-make-dispose line into a planet friendly and profitable circle, just opened a fully automated recycling plant integrated with smart robots to recover valuable high-purity materials from C&D waste.

Retaining the complete value of C&D waste.

200 tons of mixed demolition waste sorted in a single hour.

Recovered material converted into a new kind of concrete.

Robots at work

ZenRobotics’ heavy duty robots do the hard and dirty job at this plant. They pick up to 12,000 items per hour with up to 30kg weight, separating mineral materials and foreign impurities from mixed C&D streams. The new plant sorts 200 tons of mixed demolition in a single hour, but these robot sorters don’t get tired. Instead, they can operate around the clock.

.png?sfvrsn=48509761_0)

_oct.png?sfvrsn=926fb1a4_1)