Making better use of materials

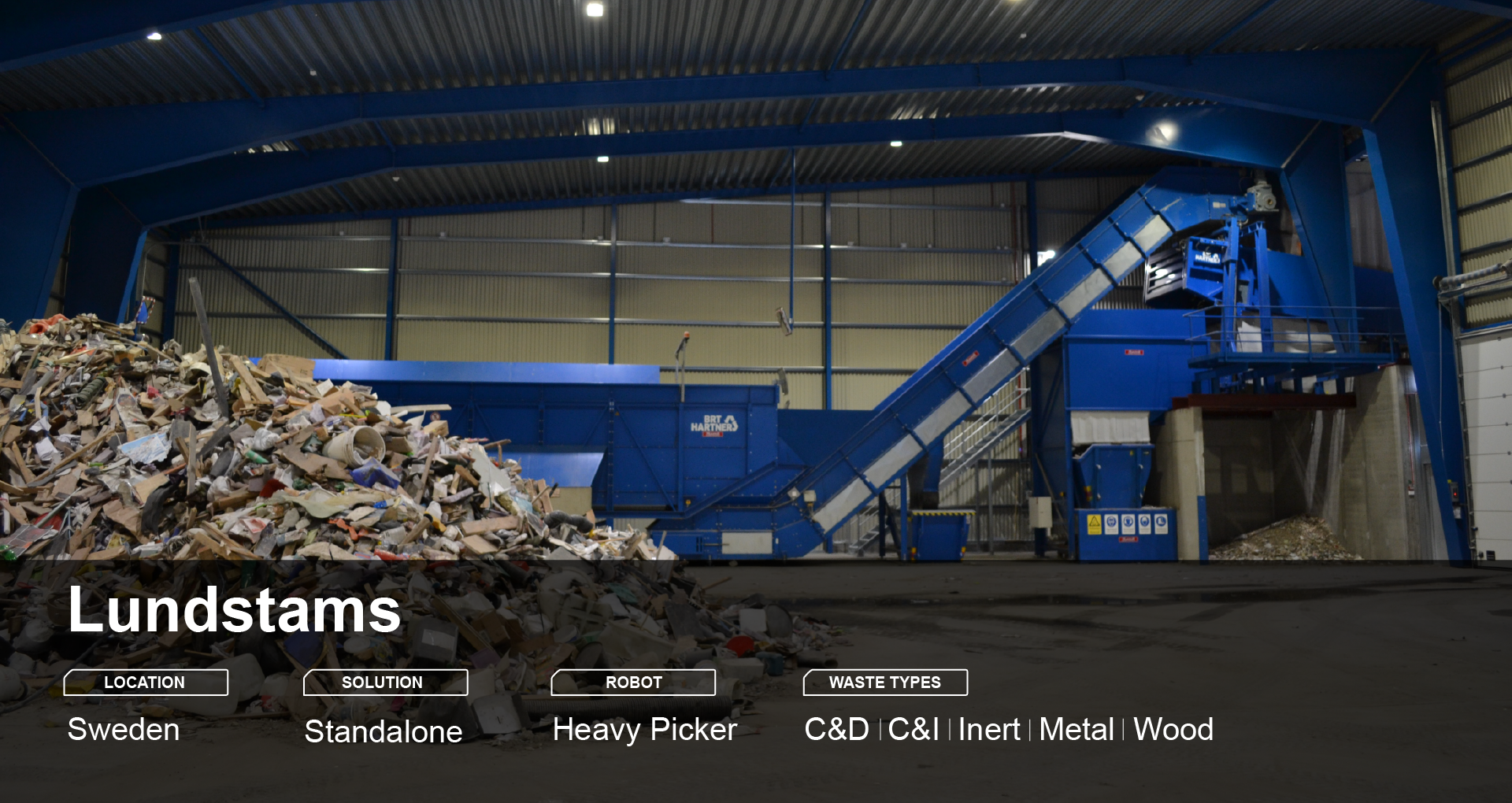

Determined to work towards improving material circulation, Lundstams is making better use of materials that were wasted before.

The new robotic sorting line will automate and advance the company’s waste sorting operations, increasing the overall material recovery and securing the quality of sorted fractions. Additionally, the need to transport waste decreases when waste can be processed closer to the source.

Applying robotics to recycling has brought cost of savings to approx. 20,000€ each month.

Lundstams has seen efficiency increase by 20x when compared robotic solutions to manual processing.

ZenRobotics helps Lundstams achieve their goal of fossil - free operations in near future.

Sustainability in focus

The company has always aimed to be ahead of the curve, offering waste management solutions with the help of advanced technologies.

Lundstams is committed to sustainable operation and the site is expected to run fossil-free in the near future. The site is already equipped for introducing electric process equipment and solar panels in the coming years.

.png?sfvrsn=48509761_0)

_oct.png?sfvrsn=21885532_1)