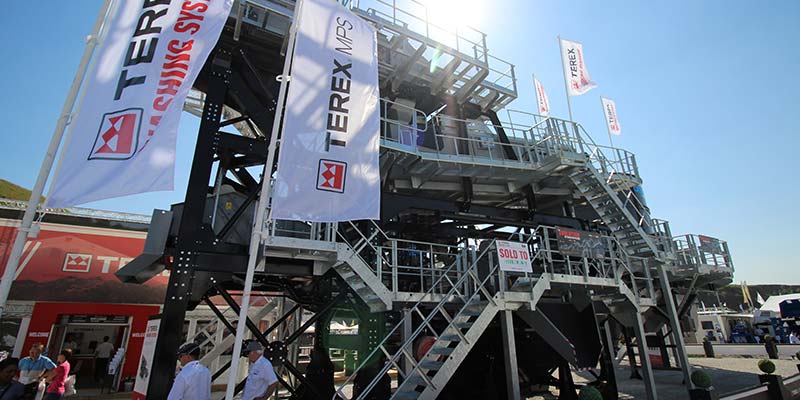

THE FUTURE OF WASHING RECYCLING

IS HERE

The world’s first modular scrubbing station to integrate heavy attrition with sizing, lightweight contaminants removal and hydrocyclone based fines recovery in a single highly portable chassis. AggWash is a rapid-install solution for a wide range of applications within the aggregates, recycling, remediation and mining sectors.

Primarily designed for the processing of construction and demolition waste but equally suited to virgin material applications. The AggWash is capable of producing four grades of aggregate and up to two grades of sand . AggWash 60-1 was Winner of the 2010 World Demolition Awards.

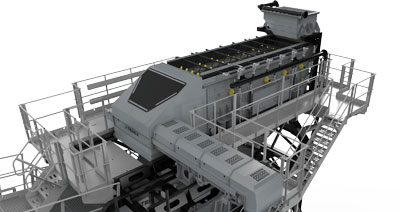

▪ 4.9m x 1.5m (16’ x 5’) triple deck Terex® Cedarapids LJ-TS Series horizontal screen

▪ Three shaft vibrator mechanism

▪ Provides high G force along with the efficient oval motion

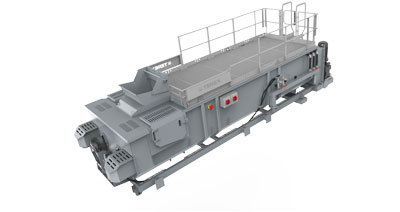

▪ Twin shaft logwasher with angle adjustment

▪ Conglomerates broken up

▪ Organics & lights floated out

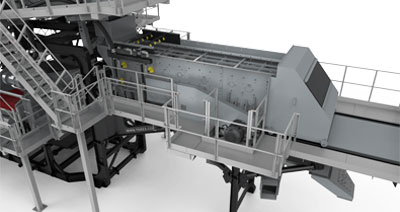

▪ Integrated 1 or 2 grade sand plant

▪ Rubber lined pumps and hydrocyclones

▪ Available in various configurations and capacities

▪ 4.9m x 1.5m (16’ x 5’) triple deck, part rinsing Terex® Cedarapids LJ-TS Series horizontal screen

▪ Producing up to 4 washed aggregates

• Large capacity wash box

• TSV5163 full rinser screen box - PU or wire mesh decks

• Variable stroke angle

• Elliptical throw for precise fine aperture screening

• All around walkway access

• 14 isolated spraybars

• Protection deck as standard

• Rubber lined roll out discharge chute complete with integrated oversize conveyor

• Rubber lined discharge chute

• Rubber lined catchbox

• All around walkway access

• Hull access doors

• Water flush rear shaft seal complete with inline water filters

• Drive end thrust bearing to protect main radial bearing

• Dual direct drive system for even torque distribution

• Shaft timing maintained through large diameter gears

• Wear sleeve on idle stub shaft

• Rubber lined discharge chutes

• Access to top of hull

• GRP Light weight durable platform

• Elliptical throw for precise fine aperture screening

• TSV5163 part rinser screen box - PU or wire mesh decks

• Variable stroke angle

• 6 isolated spray bars

• Rubber lined catchboxes

• Rubber lined discharge chutes

• Rubber lined Roll out discharge chute

• All around walkway access