Check Out All You Need To Know

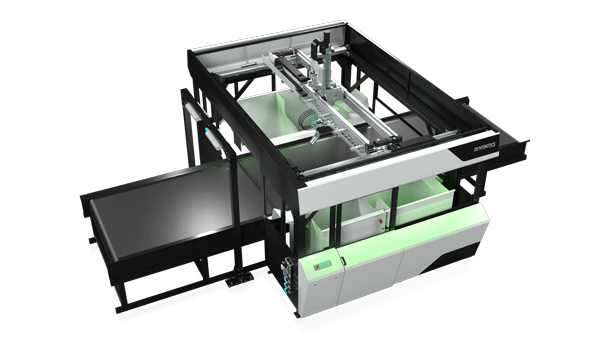

Heavy Picker 4.0

The world's strongest waste sorting robot has just gotten a makeover! Previously the Heavy Pickers AI came from a sensor box that was situated before the first Heavy Picker in a sorting station. This meant that AI connectors for multiple robots in a sorting station were all being fed data from one singular ZenBrain.

For the redesign of the Heavy Picker, there is no longer a singular recognition system at the start of a standalone solution or for a retrofitted robot/s.

Each Robot will now have its own Recognition System (ZenBrain). The Recognition System is now more compact than ever. Due to this space now being reduced, commissioning time is now shorter and it is easier to plan layouts. ZenRobotics NEW sensor recognition system is now placed before each robot. This achieves 60-100% increased efficiency among the Heavy Pickers in a sorting station, as each robot has its own AI and sensors. With the new sensor recognition system, our customers can benefit from our global training database. New installations with ZenRobotics 4.0 systems will come with a pretrained classifier, which speeds up commissioning times and customers can benefit from our superior AI that has been training for all of these years, recognising over 500 waste categories.

With an upgraded AI technology now implemented into the Heavy Picker, using deep learning technologies has improved the motion control of the robot. The new sensor recognition system scans the conveyor belt and the AI recognises the different materials coming through. The AI for the Heavy Picker generates the handle (picking location) and calculates the optimal picking order of the objects. The Heavy Picker will then sort the resource that has the most value to the customer as a priority. Our customers can tailor their resource needs by customising those values to suit them. A useful feature with the interchanging of price in raw materials - tap into new markets at a touch of a button!

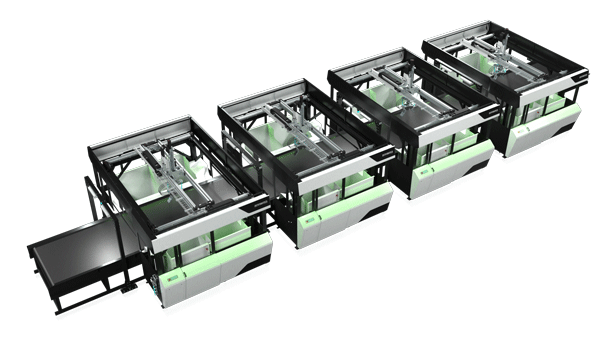

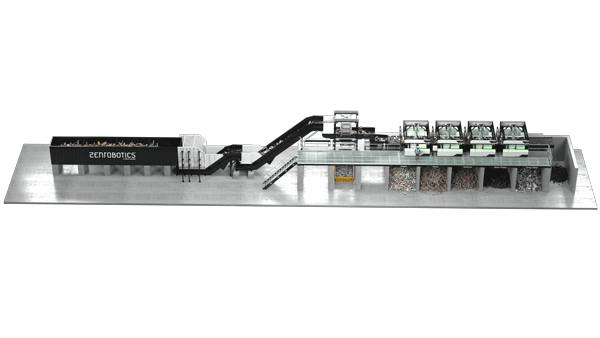

Another advantage of ZenRobotics 4.0 for our Heavy Picker, is that it's standalone solution - a fully automated and independent waste sorting station - can now include as many Heavy Picker's as required. That is 2,300 picks per hour for each robot

on a sorting line. With more robots on a standalone solution, you can have as many fractions are required. Not to mention the biggest change in our standalone solution - Fast Picker's can now be included. This enables our robots to pick many types

of raw materials in a singular waste stream. The Heavy Picker can sort bulky waste, now weighing up to 40kg, such as C&D, C&I, Wood, Mixed Inert, Scrap Metal, Rigid Plastics, Black Plastics and Bag sorting, while the Fast Picker can sort Light Packaging

Waste such as DMR and MSW.

On top of that, the Heavy Picker has reduced in moving mass which makes it easier for installation, transportation and improves the lifespan of our robot. With less mass, it brings less force and wearing for a more efficient Heavy Picker. Not to mention its reduced power consumption, the robot is more cost effective than ever before.

Customer Testimonials

Multimedia Gallery

Provide your details and we will be in touch ➡

Or talk to sales directly:

Tel: +358 50 4363803

E: sales@zenrobotics.com

.png?sfvrsn=48509761_0)