Maintaining Your Insulated Booms: Part 4 – Repairing and Refinishing Fiberglass Booms

In this four-part series, Utility Pros is summarizing four Tech Tips produced by our Product Support Team. Tech Tips cover the most common questions our Terex Services Team receives regarding repairs and replacements and is meant to provide service personnel with information to make their jobs easier. In this series, we cover tips related to maintaining insulated booms, including:

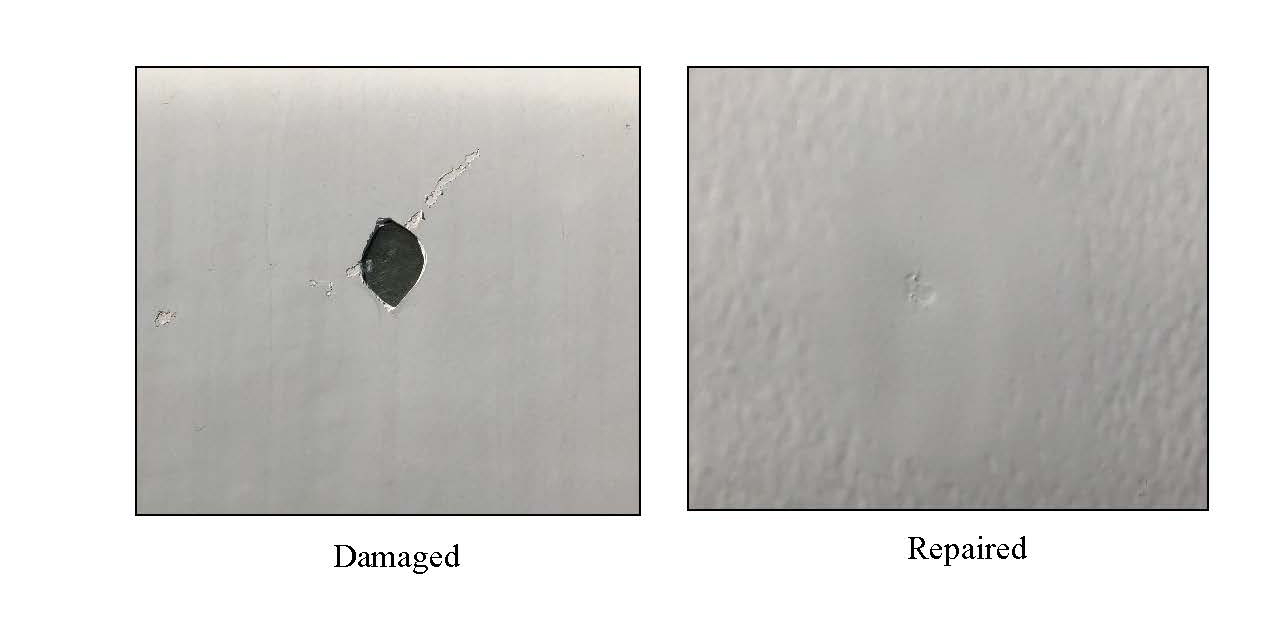

Repairing gel damage or refinishing the fiberglass boom.

Damage to the booms outer gel-coat can reduce the dielectric strength of the fiberglass. Tech Tip 149 covers procedures in repairing small areas of gel coat surface damage. Before making any gel coat repairs, refer to Tech Tip 23 to determine if the boom is repairable. Remember, Major Damage must be reported to the manufacturer for analysis to determine if it can be repaired.

Gel Coat Repair

Acceptable materials for repairing fiberglass boom surface include polyester fiberglass resin, E-Glass fiberglass matt and cloth, White NeoPentyl Glycol gelcoat with wax (from Glidden, PPG and Cook), silicone spray, and hot stick wax. Verify the gel coat used does not contain conductive components or can absorb moisture.

Clean the boom surface by washing with a product that is not abrasive and does not leave a residue, such as Simple Green. Rinse, dry, and sand the damaged area, then resurface with one of the products noted above. Allow the area to dry then spray a thin layer of silicone material or coat with a hot stick wax and wipe with a lint free cloth to remove excess.

Boom Refinishing

Clean the Boom

If the area is larger than 1-inch in diameter or the boom needs to be refinished, start by cleaning the surface with something that is not abrasive and does not leave a residue. Remove the caulk seals of the fiberglass to steel joints if there is any visible rust. If Corrosion is more than just on the surface that cannot be repaired, than contact Terex Utilities Technical Support Team for further instructions.

Allow to Dry

Allow the boom to dry for 24 hours in an environment with less than 25% relative humidity. Recommended temperature is between 100 to 140 degrees.

Thoroughly sand the outside surface less than .015 inches (.38 mm). Once sanded, only handle the boom with clean gloves. Oil and salt from bare hands can contaminate the surface. And do not expose the sanded boom to humidity over 40 percent. At this point in the process, it is important to move as quickly as possible from unfinished to refinished.

Pause for Safety:

If the reason for refinishing the boom is because it failed a dielectric test you may want to retest after removing the gel coat to determine if it solved the problem. Part of the initial inspection should have included a visual inspection of the interior for contamination, oil leaks, conductive hoses, or indications of flash over.

Resurface and Air Dry

Resurface the boom, referring to manufacturer instructions for minimum and maximum thickness range, as well as how thick of a coat is permitted in one application. Air dry the boom at 77 degrees for 12 to 24 hours, then caulk fiberglass to steel joints. A gel coat with a wax layer or the addition of hot stick wax or silicone coating is recommended to encourage water to bead on the surface.

Perform Required Testing

After reassembly is to complete an operation test from lower and upper controls. Successful completion of a periodic dielectric test per ANSI A92.2 table 2 is required also repair any issues which caused the damage to prevent future damage before placing the unit back in service.

Related Posts

Maintaining Your Insulated Booms: Part 1 – Understanding the Extent of Damage

In this four-part series, Utility Pros will summarize and share four Tech Tips produced by our Product Support Team. Tech Tips cover the most common questions our Terex Services Team receives regarding repairs and replacements and is meant to provide...

Continue Reading

Maintaining Your Insulated Booms: Part 2 - Photographing Major Fiberglass Damage

Major damage to an insulated boom must be reported to the manufacturer for analysis to determine if it can be repaired. To receive the appropriate support and possible repairs from the Terex Services team, it is important to take quality photos that depict the damage the most accurate way...

Continue Reading

Maintaining Your Insulated Booms: Part 3 – Maintenance of Fiberglass to Steel Joint

One of the most common fiberglass maintenance points on a unit is the caulking or sealant at the fiberglass to steel joint. Improperly maintained joints can lead to corrosion of the steel boom section, moisture and...

Continue Reading

.png?sfvrsn=cfc0900d_0)