Terex Washing Systems Divert Waste from Landfill with Wash Recycling Plant

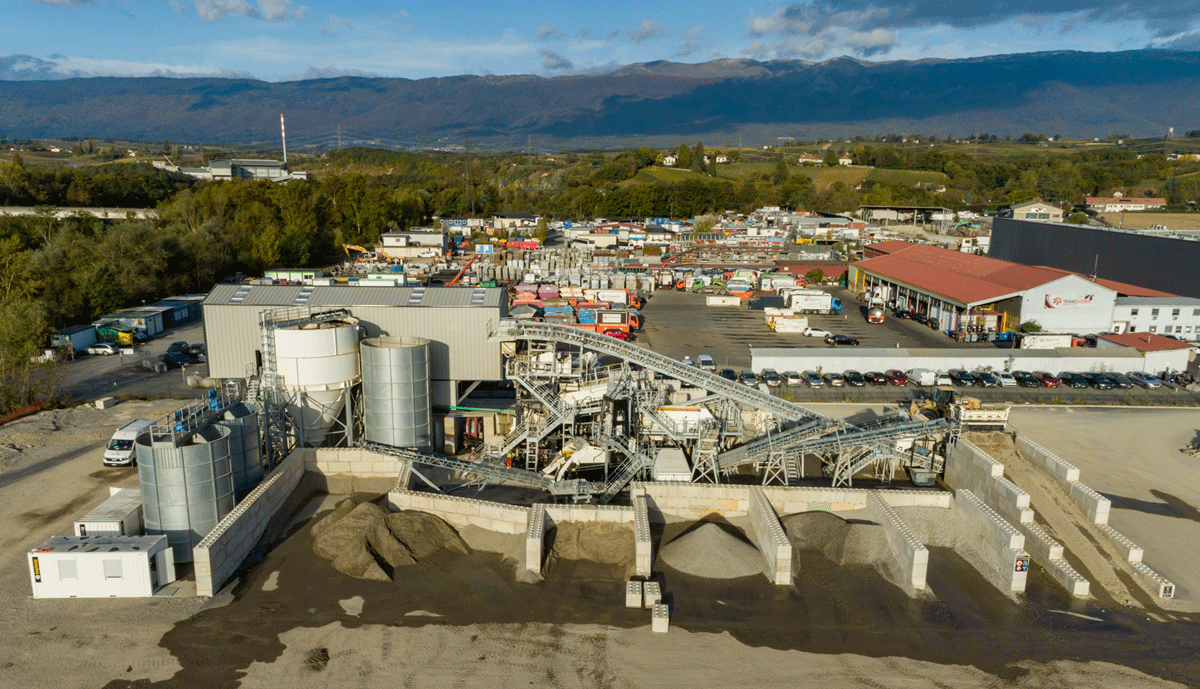

Terex Washing Systems have completed the installation of a wash recycling plant based in Geneva, Switzerland. The wash plant converts construction, demolition and excavation waste into two sands and three aggregate products that are stockpiled for use in the production of asphalt. All this is achieved while recycling up to 95% of the water used during the washing process.

A complete crushing, screening and washing solution was provided to the customer on a compact footprint in order to meet their specific requirements. The Terex Washing Systems engineers used over 60 years of industry experience, along with a product from their sister company Terex MPS, to find solutions that would meet the needs of the customer. The aim was a throughput of 100 tonnes per hour with the option of crushing oversized material included.

The wash plant consists of an FM 120 C-2G Sand Plant, an Aggrescrub 150 Log Washer complete with pre-screen and a Terex MPS Impact Crusher. This section of the wash plant washes, classifies and stockpiles aggregates while recovering two specifications of sand. Any oversized material fed into the system is directed towards the Terex MPS crusher where it is crushed down to a manageable size before being fed back into the washing system. The customer can also feed oversized material directly into the crusher.

A fully integrated water treatment plant, that consists of a Deep Cone Thickener, Flocculant Dosing Unit and a Filter Press, allows up to 95% of the water used in the washing process to be re-used. The dirty water is collected in a sump before being treated and allowed to settle in the Deep Cone Thickener. The thickened sludge is then compressed within the Filter Press so that the last remaining water is sent back into the system. The customer is then able to sell the filter cakes that are expelled from the Filter Press.

The Geneva based customer is now able to divert thousands of tonnes of construction, demolition and excavation waste from landfill each year. They can achieve this while producing six separate products to be sold or used during asphalt production and further reducing the environmental impact thanks to the water treatment plant.

Johnston Patterson, Product and Applications Manager at Terex Washing Systems, explained that, “we have provided a complete end to end wash recycling solution for the customer. Our ability to fully integrate washing, crushing and water treatment allows us to design and manufacture systems that perform to a higher standard. Everything is here, from feeder to filter press”.

This washing system provides the customer with a sustainable production line of sand and aggregate products from material that would otherwise be sent to landfill.