Choosing the Right Auger Tooling for Your Digger Derrick

When it comes to setting poles, electrical utilities and utility contractors must often make decisions on site about the best equipment and tooling for the job. Boring reports provide some insight into the geological makeup of the ground, but the reality is that the conditions can vary dramatically between locations that are just a few feet apart. Typically, digger derricks can drill 42-Inch diameter holes up to 10 feet deep.

Not All Auger Tooling are Created Equal

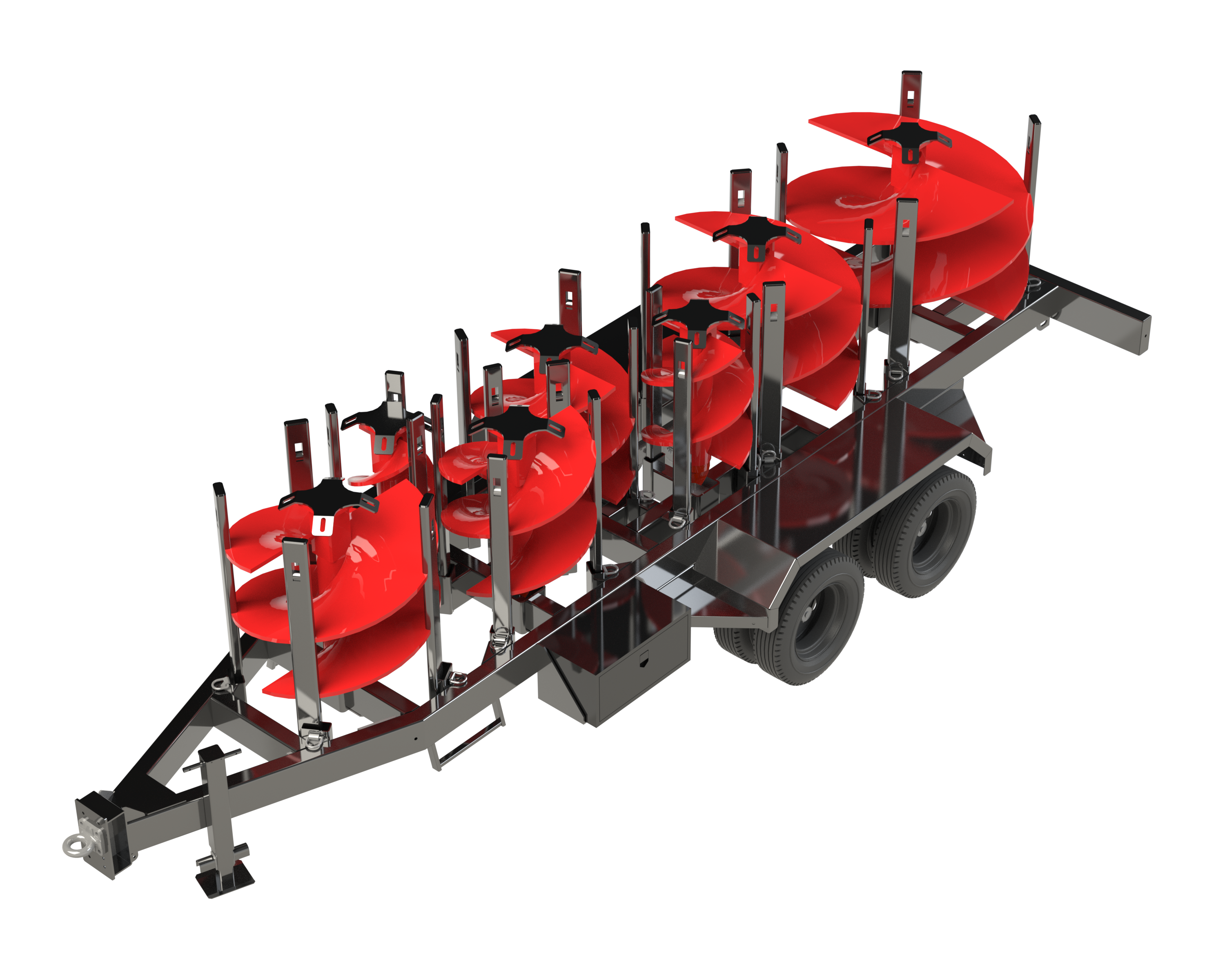

To get the best performance out of your digger derrick, it is important to choose the right auger tooling for the job. Tools are interchangeable between different OEMs, but that doesn’t mean that all tools are created equal. Terex is the only manufacturer of digger derricks that also manufactures tooling, designed for maximum productivity and efficiency. When choosing the right tool for the job, selection factors include auger style tools or barrel tools, various types of teeth, and multiple tool sizes.

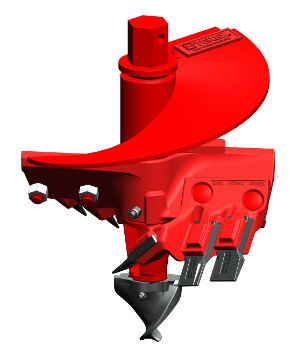

Remember, you can cut dirt with a rock auger or barrel tool, but you can’t cut rock efficiently with a dirt auger. While that maxim is an oversimplification of the selection process, it’s a good rule of thumb. Augers have flights to lift the spoils that are loosened by the teeth and a pilot bit that stabilizes the drilling process for a straight hole. See video demonstration: Terex Auger Tools Comparison

Core barrels cut a single track, applying more pressure and power per tooth, removing rock materials by lifting out the material as individual plugs. In most ground conditions, it’s best to start with an auger tool first, until you reach a point where it is not efficient, or it meets refusal to advance because the strata becomes too hard. At that point, it may be necessary to switch to a core barrel tool for better production. If you must start with a core barrel tool on a digger derrick, you may need to use a pilot bit to hold the tool straight while starting the hole.

Be sure to match the tool with the ground conditions. Most tool specifications will include a description of the type of applications for which the auger tool or barrel is designed.

Factors to Consider When Choosing the Auger Tooling

Specifications that are important in selecting the tool are auger length, flight length, flight thickness, and flight pitch.

Type of teeth on the tool’s pilot bit is directly related to the application it’s designed to work in. The pilot bit and the flighting teeth should be compatible, with the same strength and cutting characteristics. Other

Flight length is the auger’s total spiral length. The longer the flight length, the more material you can lift out of the ground. Long flight length is good for loose or sandy soil. Flight thickness impacts the strength of the tool. Excessive flight length or thickness compared to the required strength reduces the amount of material that can be lifted especially with larger size augers.

Flight pitch is the distance between each spiral of the flighting. Too steep of a flight pitch, with loose soil, will allow the material to slide right back into the hole. In that situation, a flatter pitch would be more effective. But a steeper pitch will get the job done more quickly when the material is denser.

At any time when the auger tool meets refusal, it’s a good time re-evaluate the tool being used and switch to a core barrel style instead. By design, a core barrel single track cuts through hard surfaces better than multiple tracks produced by a flighted tool.

Some conditions, such as ground water, warrant specialized tools like drill buckets, often called mud buckets. These tools remove fluid/ semi fluid material from the drilled shaft when material does not adhere to auger flighting. Another often-overlooked condition is frozen ground and permafrost, which is very abrasive. In this situation, a spiral rock auger is able to work efficiently.

Check out our auger tooling line up here.