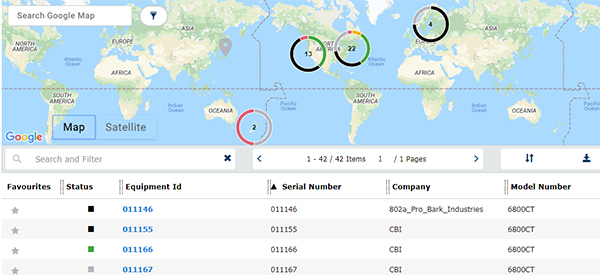

Fleet Overview

A detailed and organized dashboard lets you check the status of all your equipment at one glance. Customization options let each owner set up the dashboard to show unique analytics that matter most. Custom date ranges and instant notification of critical statuses ensure users are proactive and always informed when managing performance, maintaining the machine, and maximizing profit.

Geofencing & Timefencing

Using satellite imagery, T-Link lets users track map and terrain data, travel history, and other relevant information. Always know a machine’s current location and set alerts for when the machine leaves a pre-determined area. Users can also set parameters around certain times and know if any machine operates outside a set curfew. Great for reliable and organized documentation purposes.

Accurate Maintenance

Keep elite performance going with automatic maintenance alerts. T-Link monitors usage rates and allows for accurate forecasts for maintenance and wear parts replacements. Having CBI wear parts delivered in regularly scheduled intervals will minimize downtime and maximize profits. Take the guesswork out of your operation and know your machine is always in prime condition.

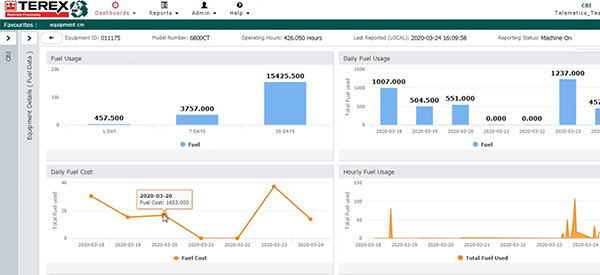

Performance

Know exactly where you stand on any given day by tracking the performance data of each machine. Users can generate accurate and updated reports of machine usage and fuel consumption to calculate the precise value of an application. Performance insights give owners a full picture of return on investment and reveal potential opportunities for profit optimization.

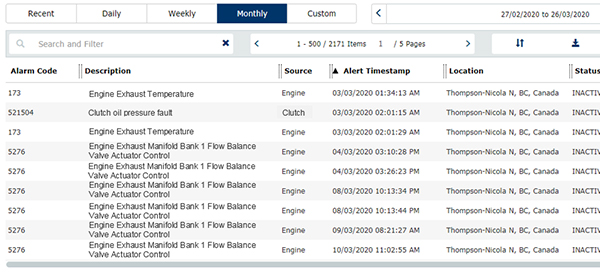

Remote Diagnostics

Receive alerts whenever there are alarms or certain codes active. Issues are immediately located and relayed to devices. Alarm codes, sources, descriptions, dates, and location make it easy for technical phone support to diagnose with solutions. Diagnostic reports allow for remote coordination with parts specialists, service teams, and product engineers at various locations for rapid response.