Equipment

Applications

Support

About

Contact

Find a Dealer

Equipment

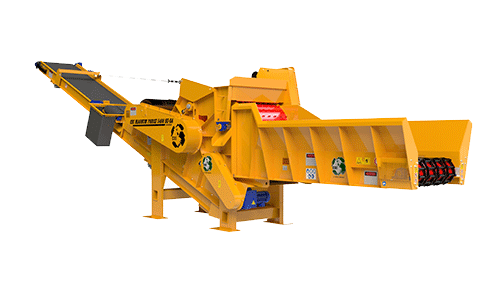

Horizontal Grinders

Whole Tree Chippers

Flail Debarkers

Grizzly Mill

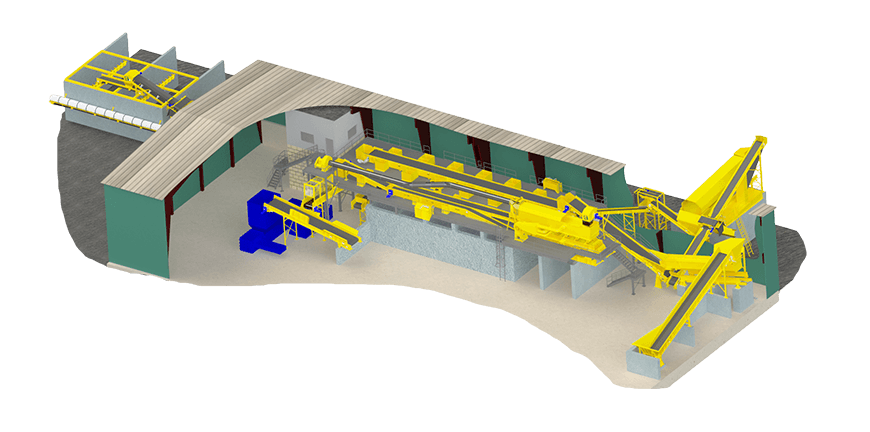

Stationary Systems

Screeners

Stacker Conveyors

Attachments

CBI Legacy Machines